Utilizing feedbacks and techniques shared by manufacturing experts throughout the industry, here’s how Artificial Intelligence has enhanced and improved your MillBox CAM Experience to-date:

A.I. makes dental CAM more intuitive

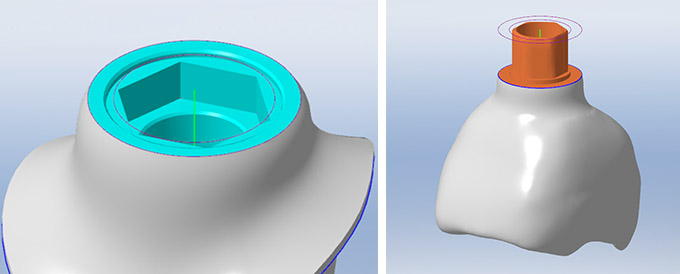

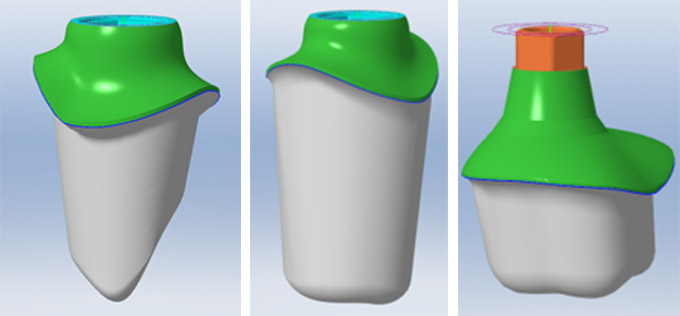

Automatic recognition of different types of implant abutment connections (Internal vs External).

Automatically separates the surfaces that make up the implant connection from its customized part.

A.I. enhances dental CAM safety

It automatically detects the area of the emergency contour with the possibility to select this part by means of a special feature and to carry out finishing operations designed to obtain an optimal result for this extremely important area in an implant work.

A.I. makes dental CAM more careful

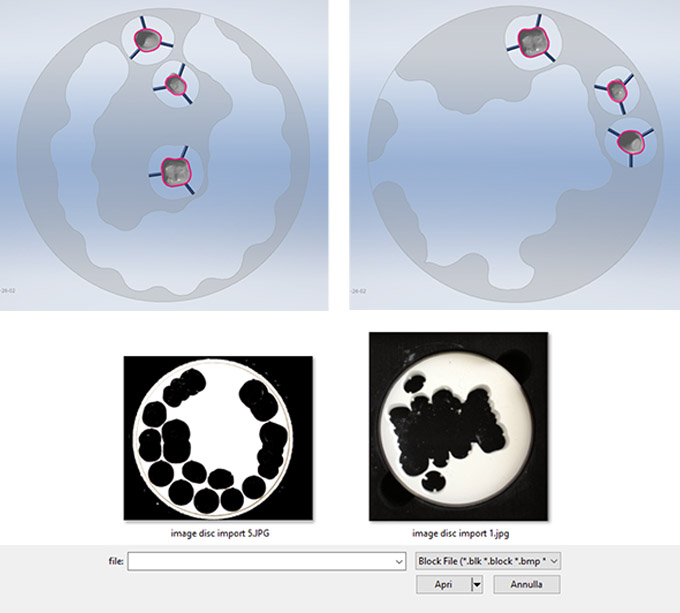

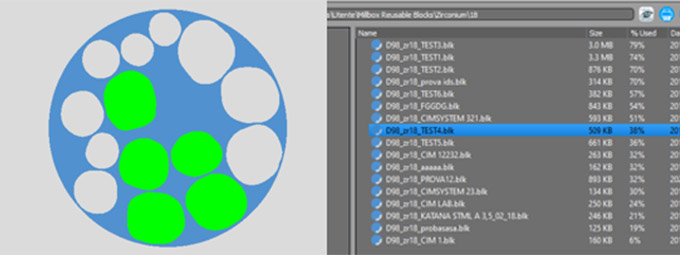

Automatic selects the most used blank based on the areas already used and the number of elements to be milled with automatic positioning of the objects.

A.I. makes dental CAM more flexible

It allows you to use residues from other CAM software as well. Importing a photo allows the recognition of already used areas and the contours are automatically reconstructed, stored as already used areas in the new blank.