3D CAM software for CNC machines and anthropomorphic robot

3D CAM software for CNC machines and anthropomorphic robot

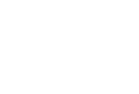

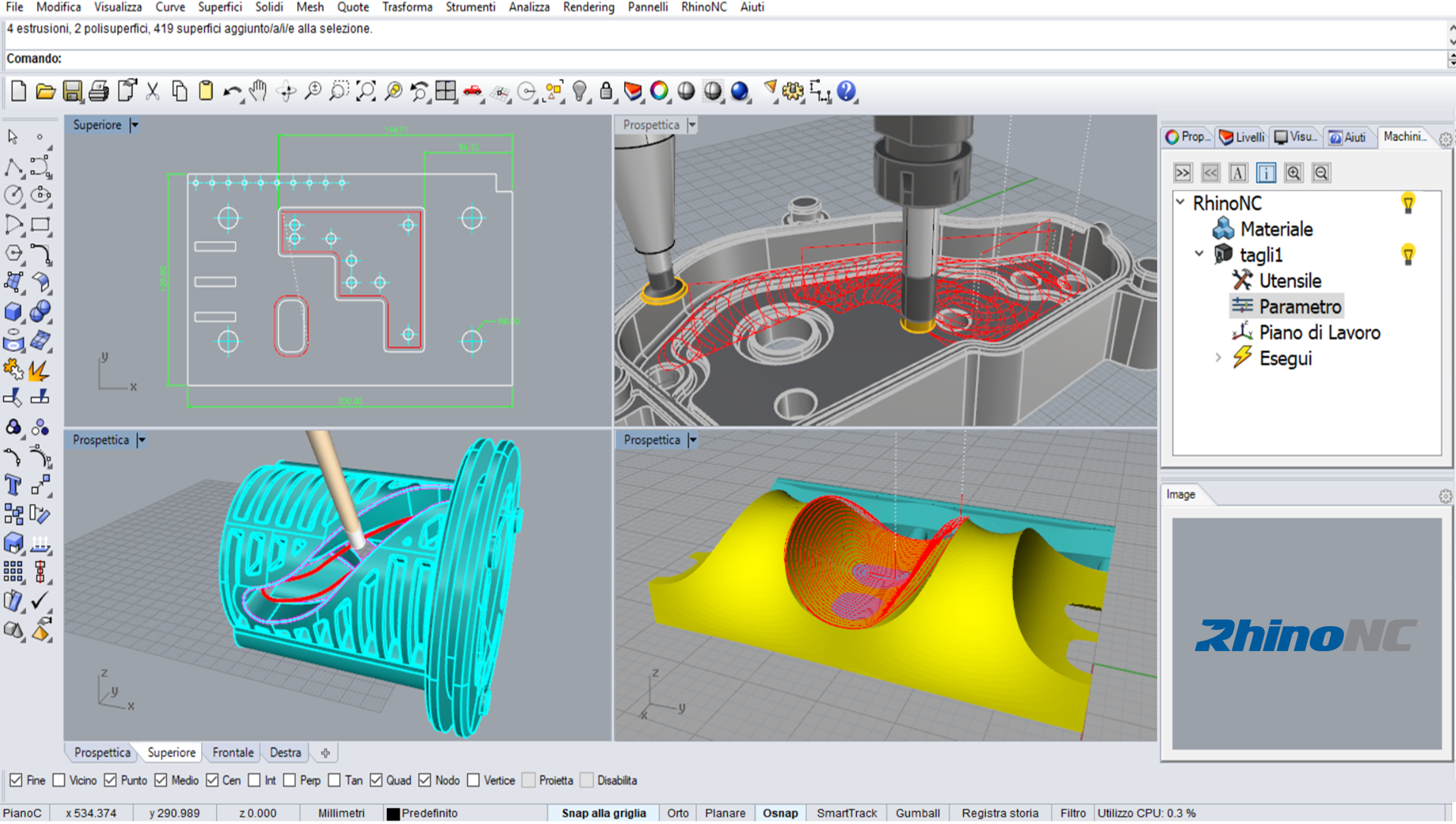

The RhinoNC interface has been completely redesigned: in particular, the machining tree, has now been widened and therefore is now easier to read. The machining tree has been moved directly into the dedicated area of Rhinoceros TABs, thus leaving more working space for the imported object. The new bar with the RhinoNC main command icons have been outlined in such a way that it integrates perfectly into the Rhinoceros icons and provides a uniform and easier-to-manage layout. The use of the software results in this way being more immediate and easy to use.

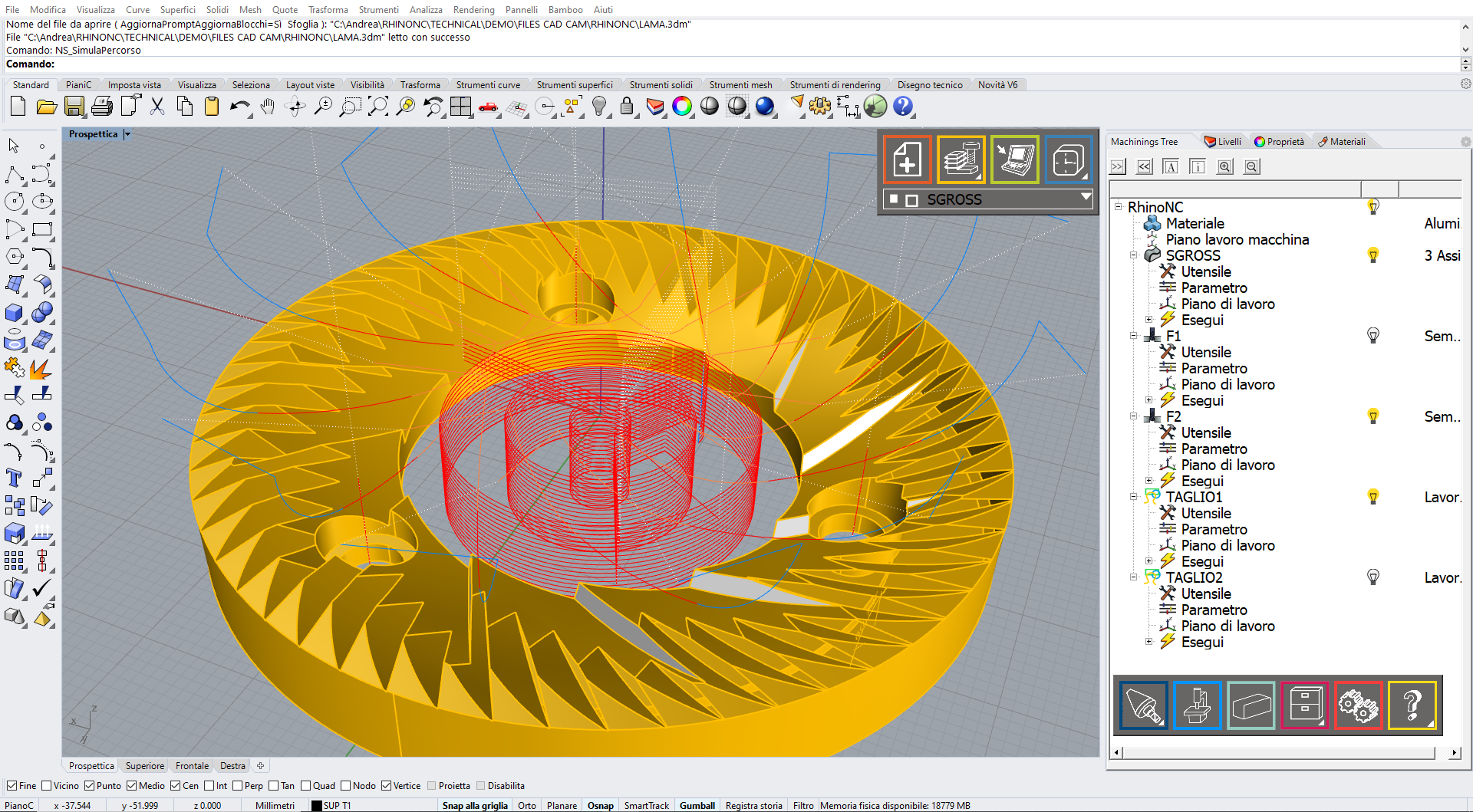

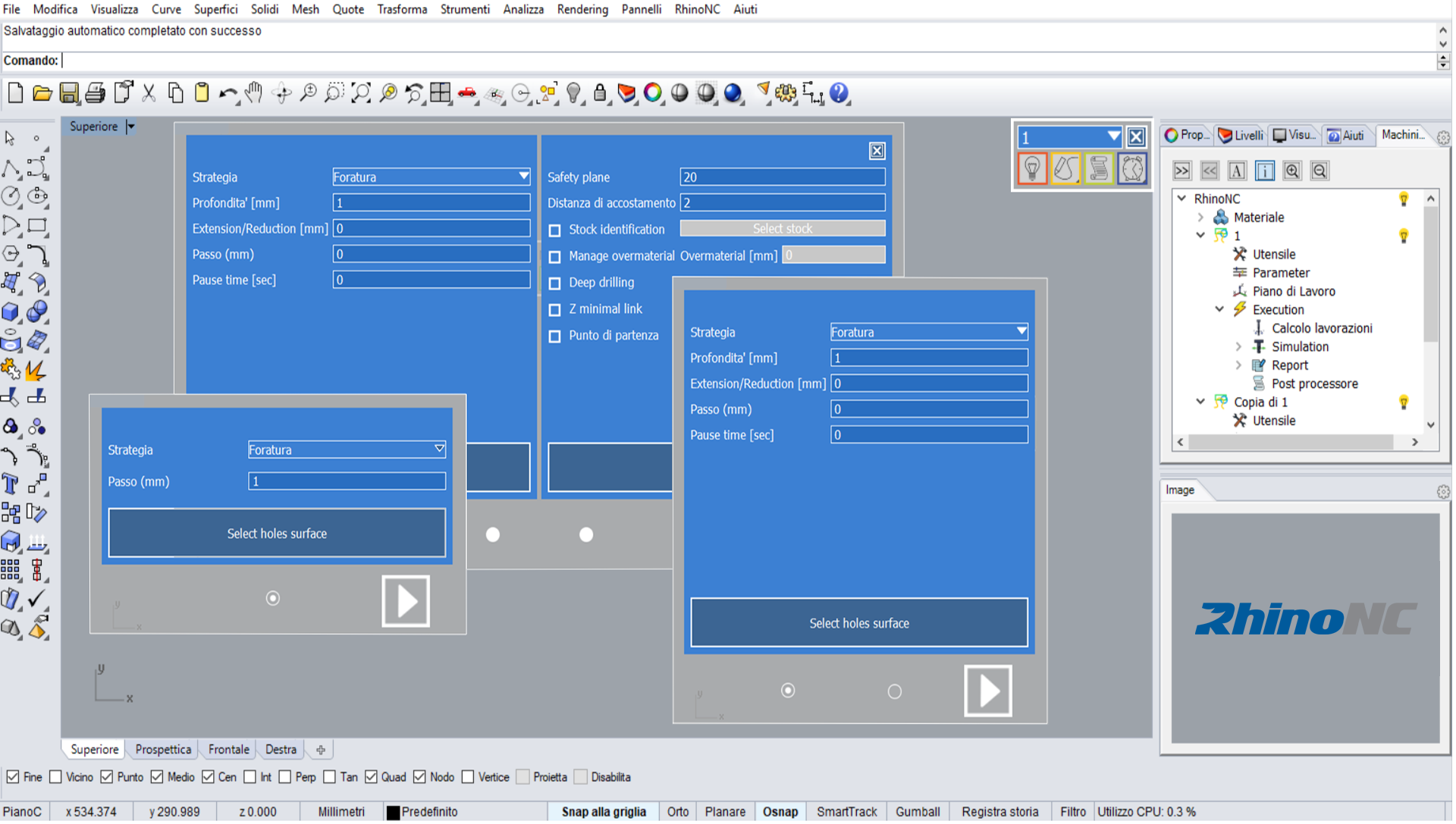

The insertion of work strategies is now managed by a new wizard. This new feature guides the user in manufacturing the part by insertion of the machining parameters step by step. This method used allows simple and fast management, without the possibility of forgetting the addition of any operations. Moreover, during the input of the various working parameters, the wizard is associates images that graphically guide the end-user’s choice of the parameters themselves, thus ensuring that the user is kept well-informed of the working strategies. This keeps the CAM under user control.

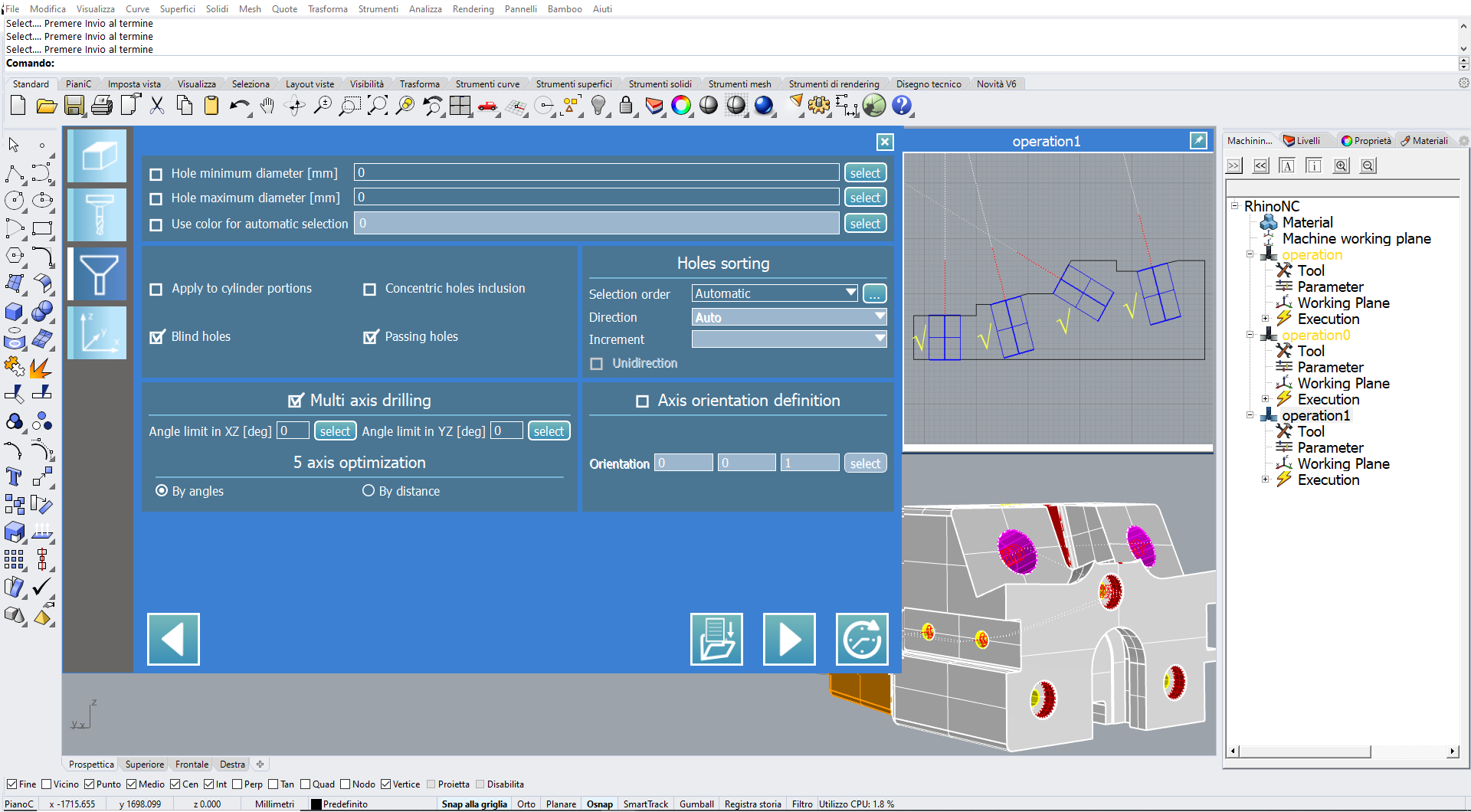

The new RhinoNC simulation bar has been rebuilt with more powerful features. It is therefore possible to check the progress of the toolpath through a simulation that manages both the visualization of elements such as the tool or the graphic path, and the speed at which the path is executed.

Another extremely useful function during simulation, especially for roughing or constant Z machining, is the ability to display the simulation one operation at a time. This ensures that it is easier for the user to determine which step of the working process they are at during the simulation.

In RhinoNC new machining operations have been introduced for the management of cutting tools that are used in some specific sectors such as the cutting of plastic material or sheet metal. Through new calculation algorithms, it is possible to create and manage new strategies with circular cutting tools such as saws and grinding wheels and to use pneumatic and manual knives. This automatically generates toolpaths that perfectly control working movements, such as: Edge management, cutting depths or the use of the machine spindle as an orientation axis.

RhinoNC introduces a new concept of workflow management: A total customization of all of the machining parameters and an interface that allows users to choose which parameters to display and hide based on preferences. The user has the possibility to utilize their own personal wizard in a simple and dynamic way – while displaying only commands that are applicable their type of work or machine. This makes the overall workflow much faster but, dynamic enough to be customizable at any step of the process – even during mid-workflow.

RhinoNC is a completely modular software: depending on the type of job and/or machines to be managed, it is possible to purchase the module that best suits your needs. Drilling, milling, cutting and welding machining can be managed by working strategies ranging from 2 up to 5 axes continuous, maintaining control of the toolpath, including subsequent 3D kinematic simulations of the machine tool.

Overview

Overview Features

Features News & Releases

News & Releases Requirements

Requirements Modules

Modules RhinoNC OPENLAB

RhinoNC OPENLAB Brochure

Brochure Video

Video