Buying a new CAM CAD software is not a one-time purchase. Though an initial purchase provides access to the solution, users need to continue to take care of their CAM software if they want to maintain a high level of quality performance and produce reliable results over time. This is where CAM software maintenance comes into play. Ongoing software maintenance helps you get the most out of your solution and is an essential part of ensuring that solution is up and running effectively, simplifying your working routine.

Here are some reasons to keep your CAM up to date:

· Improvements and optimizations

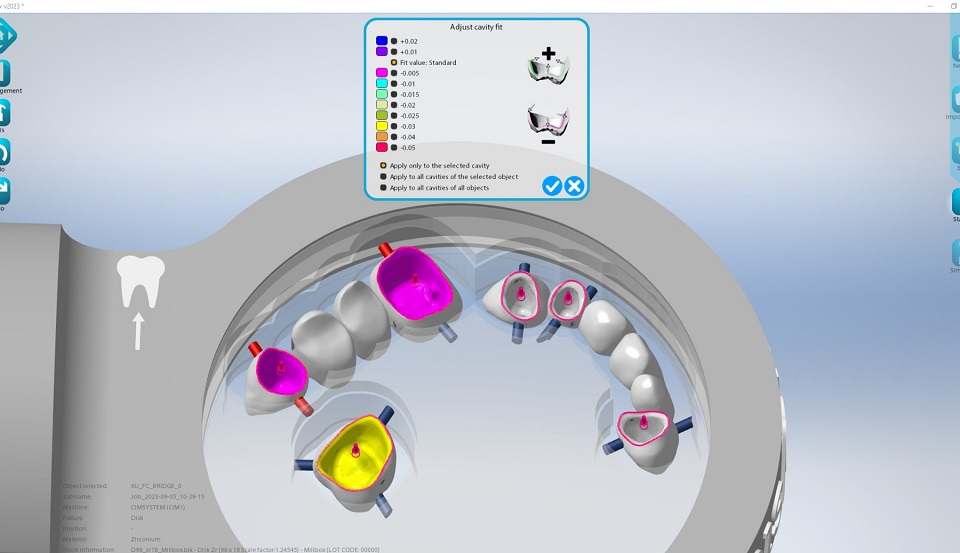

Updates frequently include improvements and optimizations that provide additional options and benefits for end users. These optimizations can save you time in the CAM and can help you accomplish complex tasks with greater ease. Indeed, optimizations and made to create a product that better responds to users’ needs. Thanks to the constant updates of our top product, MillBox Dental CAM, we ended up by enabling users to process up to 20% more units per hour.

· Overall Production Stability

Regular software updates help detect and fix errors, bugs, and security vulnerabilities, thus ensuring greater reliability of the overall system. This can help ensure that you maintain a stable production and are immune to vulnerabilities that could affect your ROI due to lost production time.

· Frequent release of new features:

Customers with access to CAM updates can stay up-to-date on all the latest features and developments being built into new versions of the software, including design enhancements, new processing options, artificial intelligence support and much more! Indeed, in MillBox we have added more than 50 features since 2019 helping many users to streamline their production while solving simple or complex issues in dental machining.

· Access to the newest tools, materials, and milling machines on the market

An up-to-date software license provides easy and exclusive access to the newest cutting edge dental manufacturing materials being developed today (zirconium, lithium disilicate, glass-ceramic, PMMA, chrome-cobalt, etc.) and allows you to use the most technologically advanced tooling being used in the market. Additionally, users who have an updated software license have access to the latest equipment innovations, giving you access to all of the newest dental CNC machines.

· Reduced Production Costs and Project Safety for management software

Well-maintained CAM software helps reduce production costs in the long run. Improvements made accessible through the use of upgraded versions can reduce computation time for certain operations and, consequently, can optimize your resources. In addition, when upgrades go hand in hand with machine tool upgrades, downtime is reduced by minimizing wasted time. Upgraded licenses also contain security patches that prevent crashes and unwanted access.

· Service and technical support

An active software maintenance service allows customers to enjoy the benefits of on-demand technical support, both in terms of remote support and pre-emption for routine and non-routine troubleshooting. In addition, customers can also take advantage of various educational opportunities, like training courses and webinars, and can receive support that helps to meet specific business needs and improve overall customer satisfaction.

In summary, regular CAM software maintenance is an essential investment for dental companies and laboratories seeking to remain competitive in the ever-changing digital dental landscape. Only through ongoing efforts to maintain and improve CAM systems can dentists, dental technicians, and dental practices ensure that they are reaping the full benefits of this advanced technology. At CIMsystem, we provide free international support to up-to-date customers, offering support both remotely or in-person, to ensure that we provide as much responsiveness to customer needs as possible.

Contact us to update your software! https://t.ly/DentalContactUs