Why Are Stabilizers Essential?

When working with sintered materials such as zirconium or cobalt chrome, volumetric shrinkage and deformation are a natural part of the sintering process. Therefore, the stabilizer support you choose can be very important. The use of an inappropriate support could cause unnecessary distortion and may compromise the quality and the precision of the finished product. The patented A.P.E. system is designed to avoid these problems, providing superior stability for your milled restorations.

· What is A.P.E. and How Does it Work?

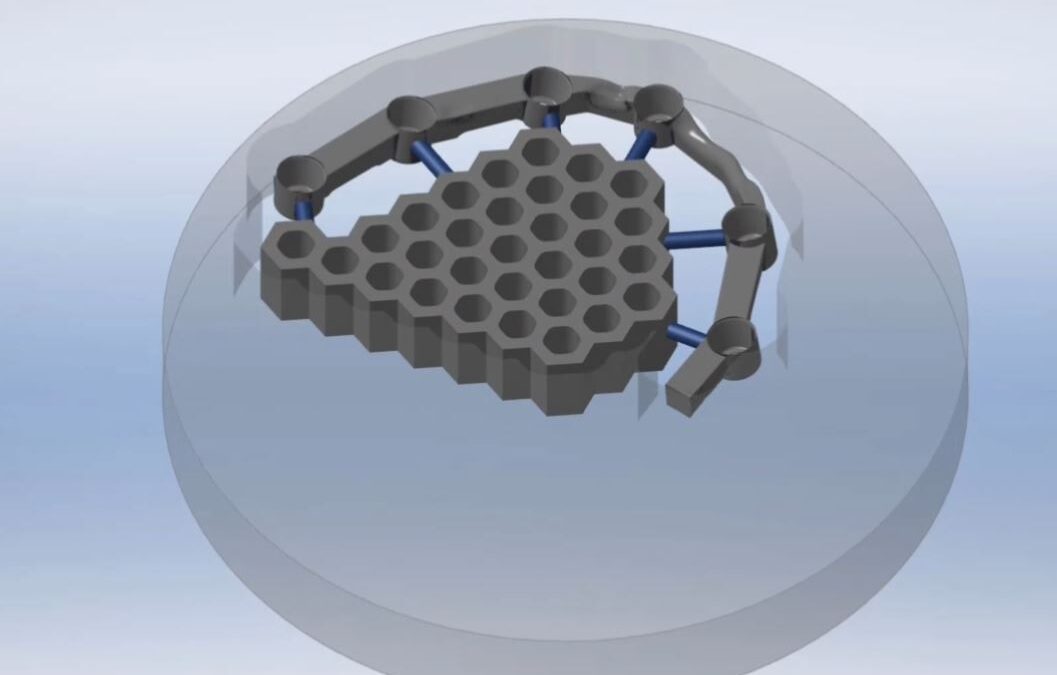

A.P.E. is a patented stabilizer system optimized for sintered metals. Available in different heights (4 to 10 mm), this innovative system provides: ✔ Uniform force distribution ✔ Uniform thermal distribution ✔ Optimized linear contraction. And it also helps to: ✔ prevent distortion ✔ counteract twisting forces. Thanks to its modular and customizable shape, A.P.E. adapts perfectly to the shape of any dental structure you need to produce. Its unique honeycomb platform ensures a solid and stable base, minimizing any possible contingencies during sintering.

· How to Choose the Right Height for A.P.E.?

Choosing the right A.P.E. stabilizer height is critical to achieve perfect results. Therefore, we are happy to provide you with some general guidelines: 🔹 4mm – Ideal for low volume structures 🔹 6mm – Most recommended solution for stability and optimal results 🔹 8mm – Perfect for more substantial structures 🔹 10mm – To be used for very tall, irregular and complex structures.

· Compatibility and Ease of Use

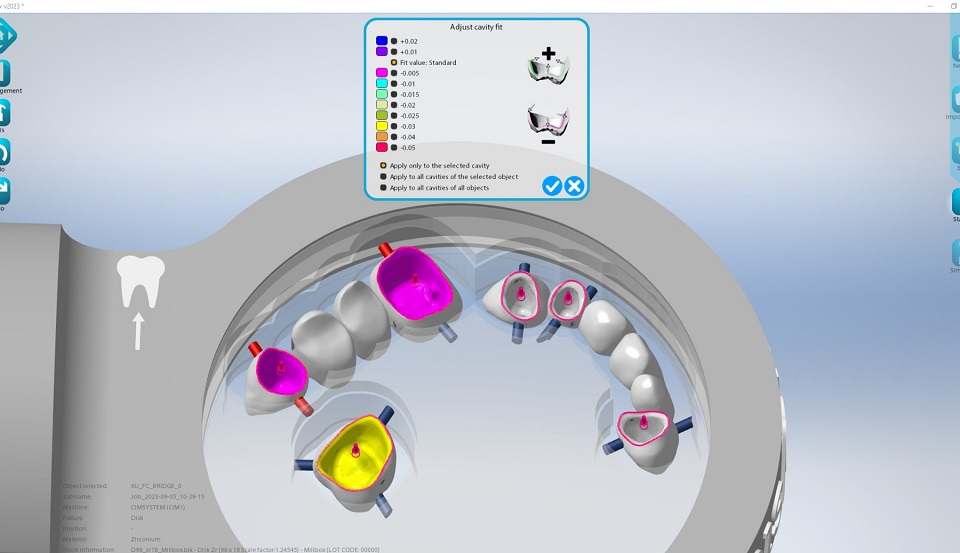

Originally designed for Amann Girrbach’s Match2 CAM, A.P.E. is now also available in MillBox, expanding its compatibility with all metal milling machines. Using A.P.E with MillBox is even easier and more intuitive than CAM Match2, thanks to the software automations that help the customer create their parts in just few steps.

Additionally, MillBox automatically suggests the stabilizer shape that best fits your project, automatically selecting the ideal height to ensure uniform force distribution. The software also allows the stabilizer to be modified and customized in just one click, optimizing material consumption and improving the overall stability of the restoration. A.P.E. cells can also be added on removed according to individual user preferences and requirements.

Thanks to the power of software automation, the entire sintering process is now faster and more accurate because of the combination of MillBox and A.P.E.: the easiest and most effective method for sintering pre-sintered metals.

Learn More

Want to see A.P.E. in action? Watch our video on A.P.E. in MillBox and learn how to improve the quality of your dental work with an innovative and reliable system! Contact CIMsystem to receive a FREE trial of MillBox. Note. A.P.E usage needs to be activated by CIMsystem or an official MillBox Reseller. 🚀 Elevate your standards with A.P.E.!

A.P.E informational materials provided by Andrea Bortesi Laboratory. Ask for A.P.E Stabilizer activation: https://t.ly/DentalContactUs