To make this evolution possible, dental milling centers, dental labs, and solutions providers invested their resources into developing efficient machines and high-performing software to digitalize the entire dental workflow.

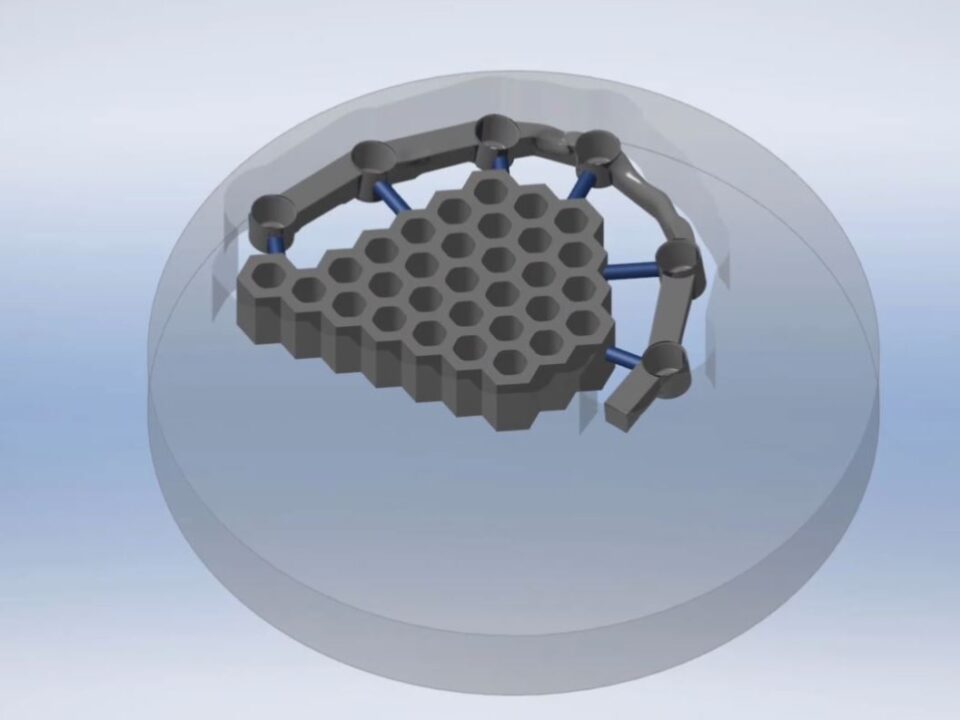

The main objective was to be able to go from intraoral scanning to final restoration without performing manual operations. This objective necessitated research to find the best mix between machines, CAD/CAM software, high quality tools, and operator training. Although the evolution of dental milling technology has now made it possible to fully digitalize laboratories and/or milling centers, it is difficult to achieve 360° digitalization on all components.r cost, with incredible accuracy, and with beautiful aesthetics.

So, how do you choose the best CAM software for your dental laboratory or milling center?

Here are 5 easy tips to get you started

- Know your patients’ needs: Based on the variety services offered in the modern dental laboratory, it is crucial to choose the type of CAM that is most efficient and effective. Some solutions are more specialized to process complex restorations, while others are more suitable for standard jobs.

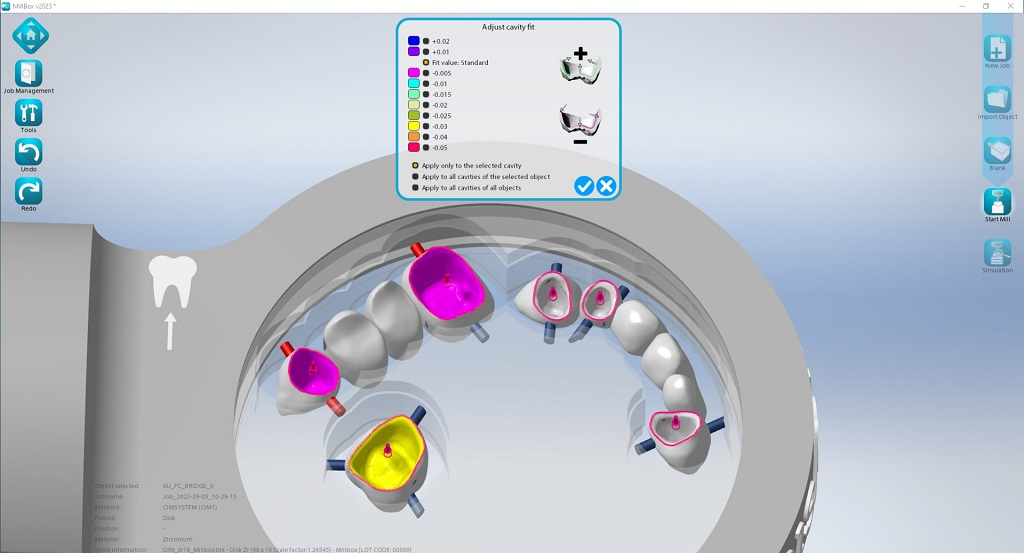

- Usability: When selecting a CAM, our suggestion is to select a solution that has an easy-to-use interface and promotes quick learning, minimizing the learning curve even for new operators.

- Post sales assistance and technical support: Choosing a CAM software supplier that offers efficient and responsive technical support is essential to maximize the efficiency of your laboratory. Additionally, access to high quality training and resources helps to expedite the learning process.

- Software integration: A fully open CAM software is the best solution you can choose. An open CAM allows you to utilize your existing solutions, improving them with software integrations that make your workflow smooth and reliable.

- Technical updates: The choice of dental CAM software is an important investment, therefor it is highly recommended to take the necessary time to fully evaluate software characteristics and capabilities before making any purchase. Luckly the majority of the software are available for short trials or in free demo versions so that you can evaluate whether the software really meets your needs. We suggest to compare at least couple of CAD/CAM software available on the dental market to obtain a more complete view of the features and advantages of each solution.With the right dental manufacturing software, you will achieve maximum accuracy in the creation of every restorations or prosthesis as well as optimized result in less time and cost, and the entire process will be smoother.

-