Implantology is a continually evolving discipline that has been making notable progress in the design and production of full dentures used for reestablishing masticatory functions and aesthetics in edentulous or partially edentulous patients. Let’s go deeper into new material application and usage.

Why choose cobalt-chrome for dental restorations?

Cobalt-chrome is a metal alloy that has been used for medical and dental device production for decades. It is resistant to mechanical stress, durable, and biocompatible, which makes it the ideal choice for many different applications, including bone implants. Let’s take a closer look at the benefits of cobalt-chrome:

- Durability: Cobalt chrome is known for its resistance; able to withstand mechanical stress without suffering damage. This property turns cobalt-chrome into an extremely reliable material for implant bone restorations.

- Biocompatibility: Cobalt-chromium biocompatibility has been demonstrated by many research studies. This is a fundamental characteristic when considering options for implant dentistry.

- Flexibility in design: Cobalt-chrome is extremely adaptable and easy to fit with patient-tailored restoration designs. This material is used mostly to create support structures for prosthetic restorations such as crowns, bridges and bars, helping to improve the fit and stability of bone implants.

- Ease of processing: Cobalt chrome is relatively easy for dental technicians to process and allows for rapid fabrication of custom-made devices. This helps to reduce waiting times for patients and improve their overall customer experience.

Clinical case study: How to create implants using cobalt-chrome in semi-finished restorations

CEPROSEM is an Italian Milling center known for its cutting-edge technologies and highly-trained operators. CEPROSEM developed a need to create a semi-finished product for inclined holes that could overcome all the limitations present in existing applications for on-axis holes that can interfere with the incisal part of the tooth. Using only in-house assets, CEPROSEM developed a solution.

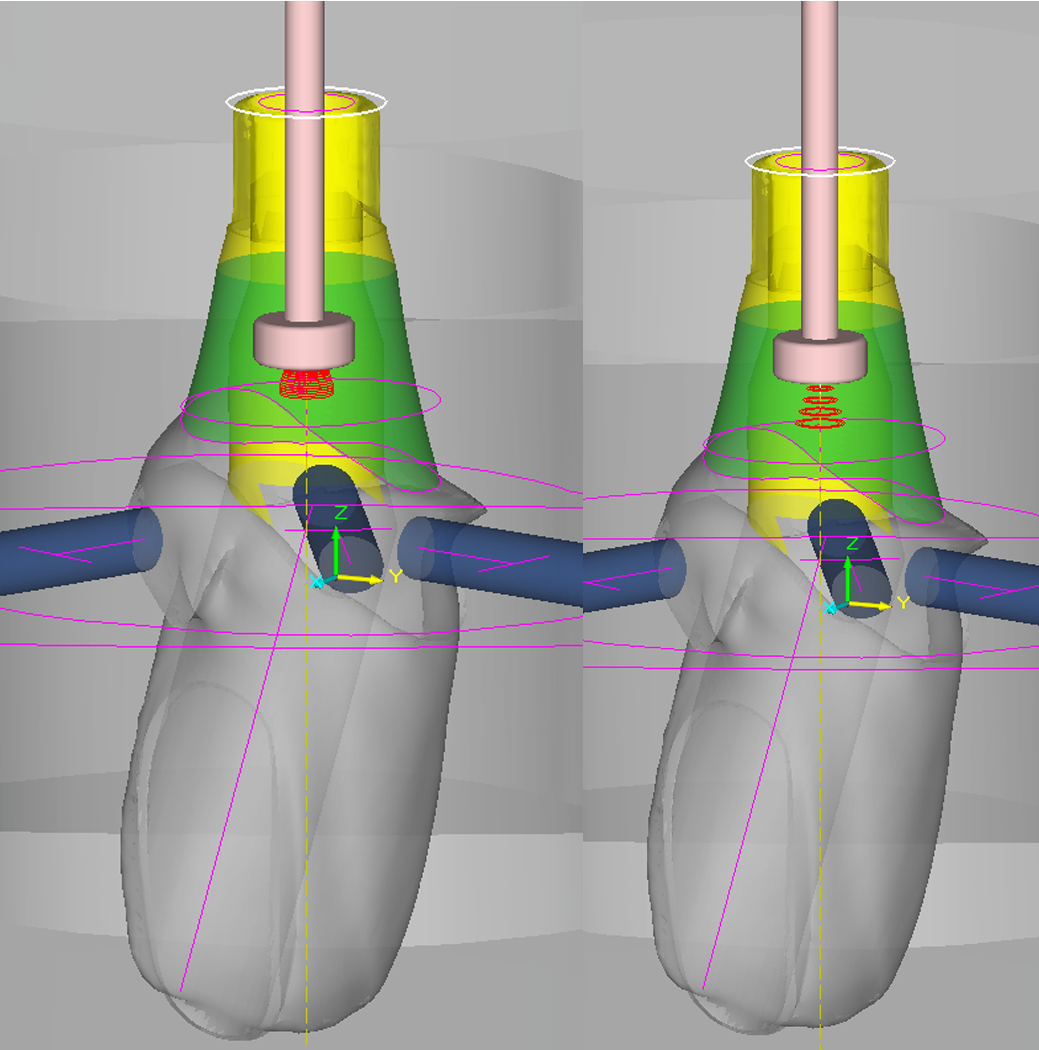

In this process, a 20° inclined hole is created with respect to the insertion axis of the bone implant and the connection is identified. Connection detection occurs automatically thanks to the specific “identification” “Identify” function present in MillBox dental CAM software. The activation of this function allows the automatic insertion of the cutting and fitting parameters for implant creation. The object is then positioned on the blank and calculated to obtain the .nc file to be sent to the machine.

After access holes have been created through multiple drilling cycles, the operation proceeds to create the inclined hole and the screwed channels on the implant. The hole on the connection side is created by standard milling operations, while the screw top refining is carried out with a special “T” tool. The match is performed by algorithms within MillBox CAM software, managing both the roughing phase and a second phase of machining with only axial micro-increments, to correctly define the screw channel. Tool life is determined based on the accuracy of the processing.

As mentioned above, performing flexible operations like these are possible due to the availability and usage of cobalt-chrome material, a versatile alloy which allows customizable design and fitting. Screw-retained cobalt-chrome semi-finished products represent a significant step in implant dentistry evolution, helping to improve the quality and longevity of implant treatments.