MillBox Additional Applications

MILLBOX

Dental CAM software for smart restorations

Some MillBox additional applications can be purchased separately or integrated in your current configuration to enhance software capabilities. You have one application for each one of the key pillars in dental manufacturing: restorations refining, strategy creation, files management, implant management.

Available as a MillBox integration, Make&Mill allows the user, within one application, two technologies: the additive and subtractive technique. Creating the object with additive technology, sintered metal or resin, the Make&Mill dental CAM allows the user to take up work again to the milling object. The benefit is double: the additive technology ensures lower cost and commitment of the operators, while the subtractive technology brings precision finishing to the surfaces of the restorations.

The new configurator represents an unprecedented leap in strategy management. It allows you to select and duplicate predefined strategies as a basic user while giving you the possibility of accessing and creating fully customized strategies as an expert, all according to your specific needs. Either way, the strategy will automatically grow and be updated with the new features through software updates, freeing you from the need to edit, test and fine-tune your strategy to keep it up-to-date. MillBox saves your time and resources and keeps you at the forefront of innovation.

FileHub is an independent browser that helps you access all the STL files you have on your computer, gathering them into a single platform. FileHub is fully integrated with both MillBox milling software and the 3D printing solution Pyramis, providing you with an overview of all your open jobs at once. FileHub gives you the unique advantage to filter all your files according to specific parameters that you can easily select and modify (such as date, material type, file size, height, etc.) to help you organize your daily milling routine.

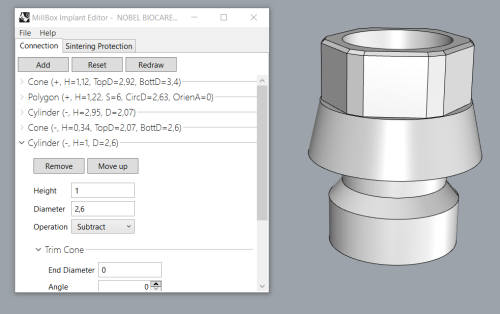

Using Implant Editor you can create custom implant connection geometries in a very easy way. The software guides you through the geometry design step by step, via basic shapes. It is possible to design optimized protections for connections to reduce both milling time and tool overuse. The CAD can automatically be imported into MillBox with perfect fitting of settings and parameters. With Implant Editor you have the freedom to design and save your library as never before and building geometries will not be an issue anymore.