MillBox Versions

MILLBOX

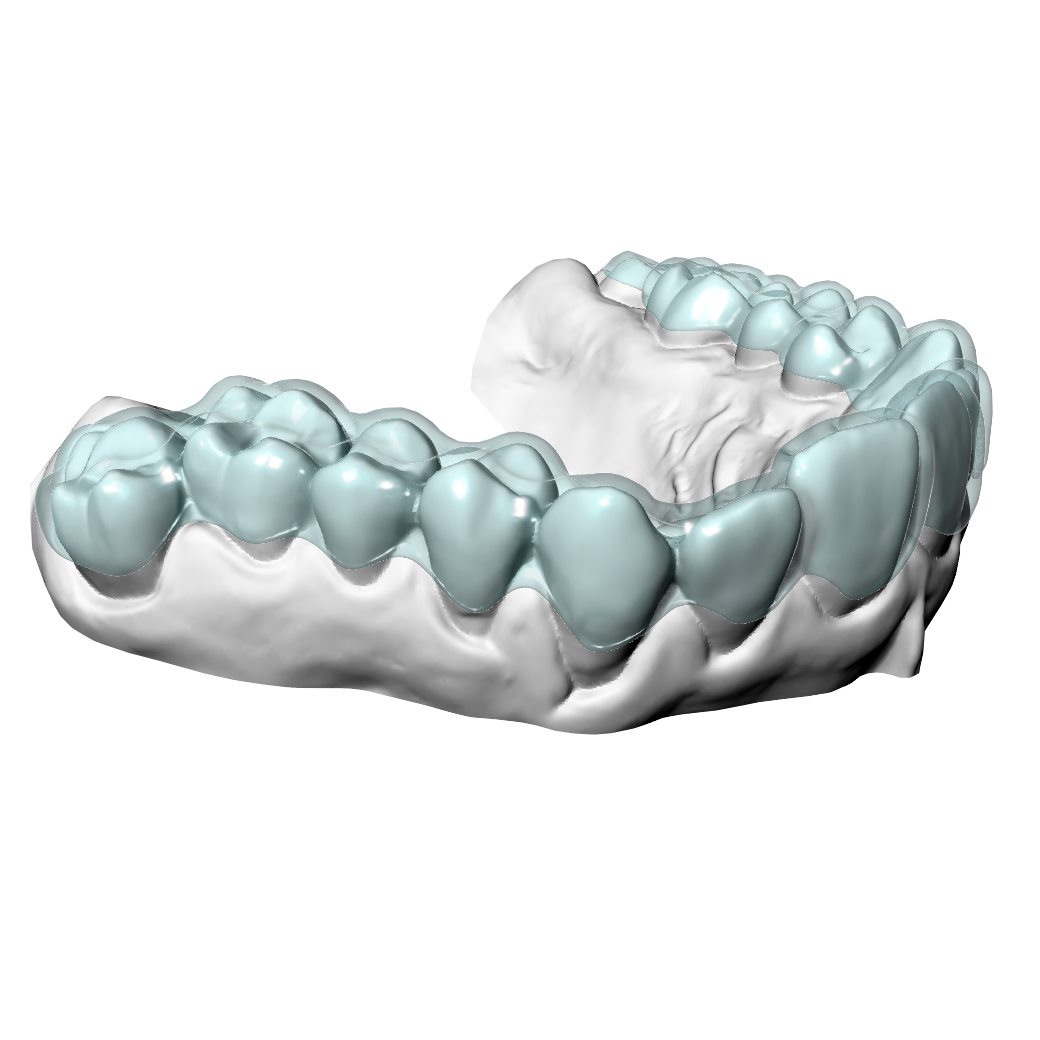

Dental CAM software for smart restorations

With MillBox you only buy what you need. Fully customizable, flexible and extremely easy-to-use, the software can be adapted to any type of workflow and productivity level as well as any open machine and any material.

We have created 4 versions of MillBox, each one levering different options to help make sure you have the best configuration for your daily routine.

Use the interactive configurator below to find the version that best matches your specific needs.

What blanks do you mill the most?

What parts do you mill the most?

How do you use the software?

Do you want to be able to customize your strategy?

Your Millbox version is ready!

We've got a great MillBox version ready for you. Fill out the information below to see your results and get more information on the MillBox version that best suits your needs.

Accessing your content, please wait...

Sorry, a server error occourred. Please wait some minutes and retry.

Submission successfull, please wait for your content.

If you bought MillBox before 2021, you can benefit from STANDARD and EXPERT version features by adding Comfort and Advanced Modules separately. To know what’s included in each module CLICK HERE