The future of dental manufacturing utilizing CIMsystem’s hybrid solutions.

The integration of different technologies within a single solution is the future of dental manufacturing. Thanks to research and development, innovative and integrated tools have been designed to digitize the whole processing workflow. CIMsystem, a leading provider of CAD/CAM solutions in the dental and industrial manufacturing industries, has always focused on innovation and the development of technologically advanced applications.

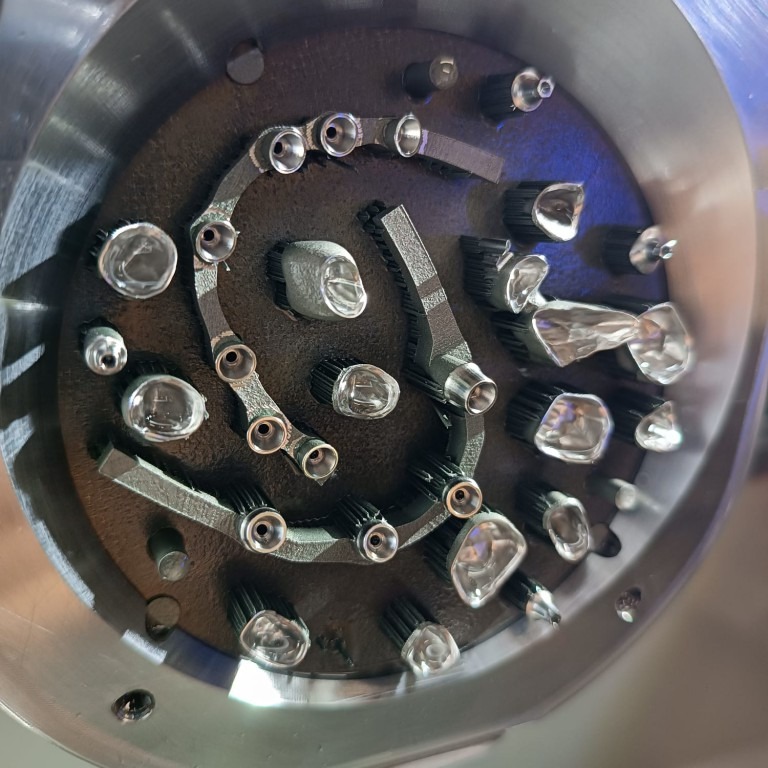

At IDS 2023 – international dental show in Cologne, CIMsystem presented a new application dedicated to the finishing resumption of a project with additive technology and a finishing resumption with subtractive technology. For the execution of the project, CIMsystem collaborated with several digital partners: Trumpf with the Lasermelting Machine and Faimond with the Dental Milling Machine.

A few of CIMsystem’s software solutions play a leading role in the whole process: MillBox, imports the dental parts to be machined and distributes/positions them in the work area, Make&Mill completes the finishing milling of the relevant positioned parts,and Pyramis, prepares the work for the printing machines (lasermelting), which is used to optimally arrange the parts in the printing space, create suitable support structures for the printing process, and finally generate the laser paths for melting the metal powder to produce the final object.

In addition, M&H’s 3D Form Inspect solution, software developed by CIMsystem, can verify and measure geometric and anatomical parts through mechanical touch systems or more advanced systems such as lasers.

The integration of these technologies make it possible for all operators in the dental industry to gain huge benefits in work management organization and productivity in achieving the highest results. Furthermore, the fusion of these technologies allows for high machining precision, especially thanks to M&H 3D Form Inspect, which is able to zero and/or modify ‘incongruent’ values with efficient alignment solutions in the centring phase.

The solution is also extremely effective for three-dimensional measurements of machined parts, as it provides detailed information on the level of precision of the machining performed.

Despite the use of technologically advanced software and machines, CIMsystem has designed and developed a simple, integrated, and easy-to-use application.

For more information:

https://www.cimsystem.com/dental/contacts