MAKE&MILL

Dental CAM for milling and 3D printing

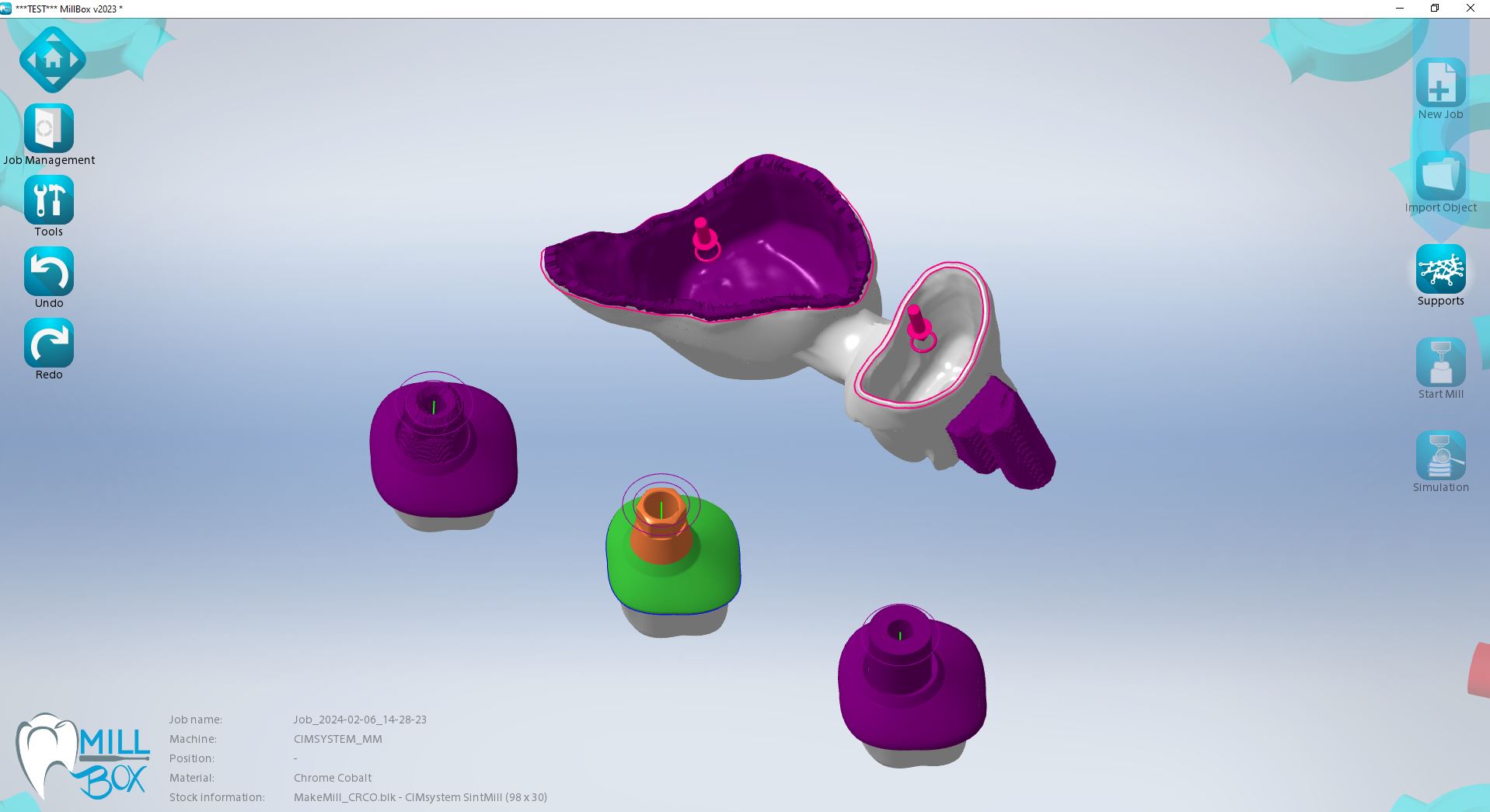

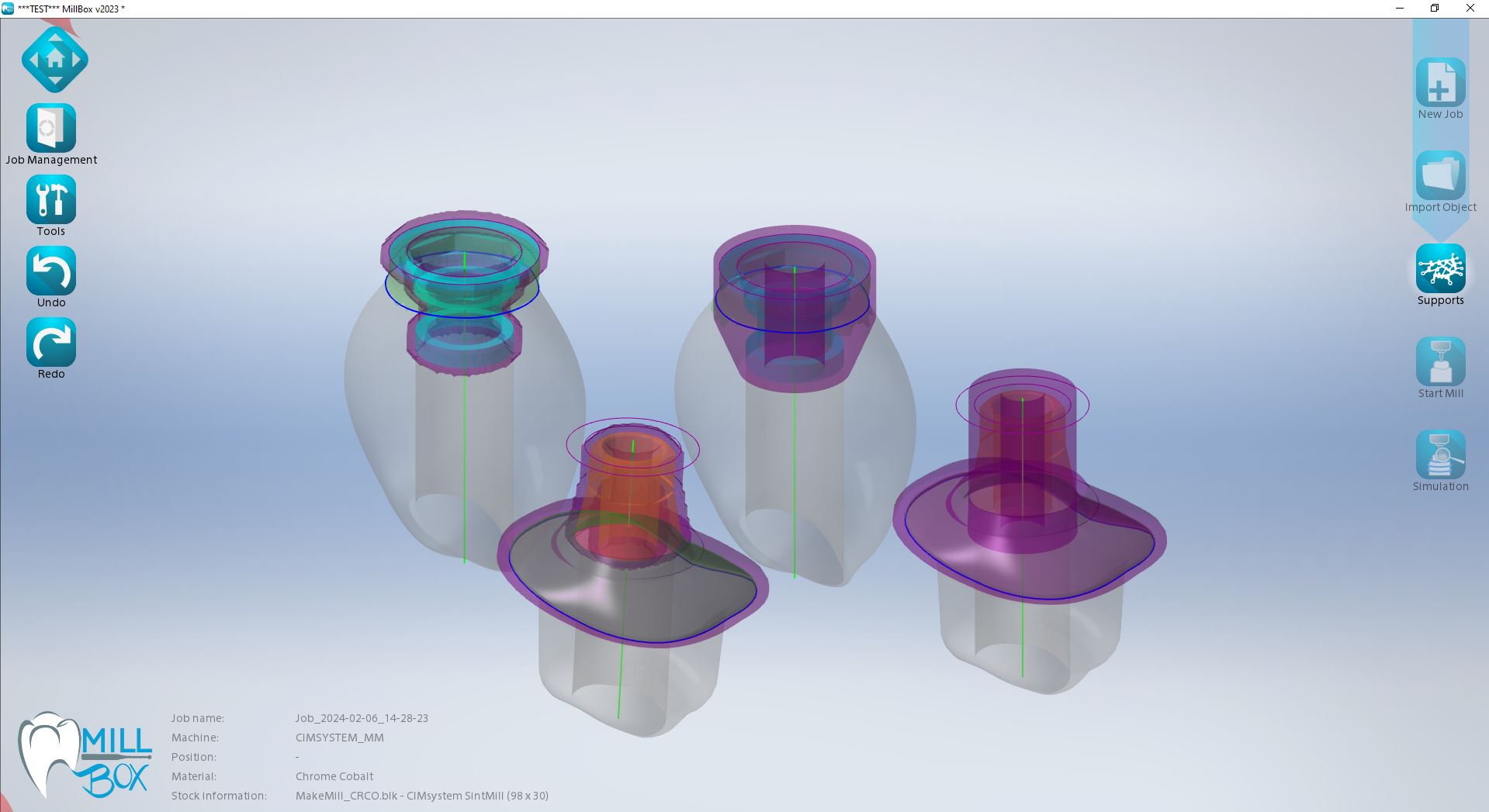

Make&Mill development generally coincides with MillBox, our premier Dental CAM software. Here are some specific features that primarily affect Make&Mill and enable the software to better perform its intended tasks.

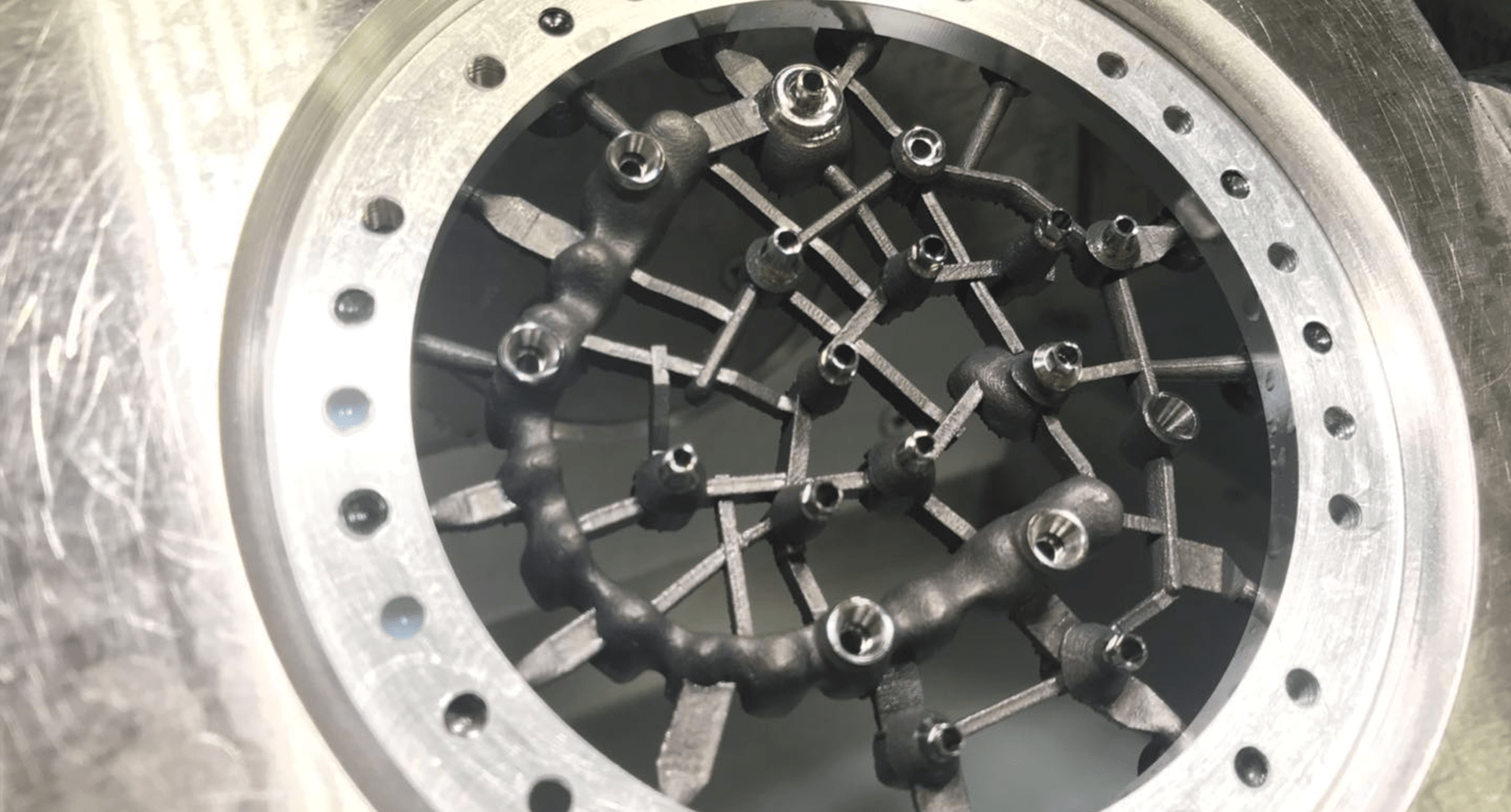

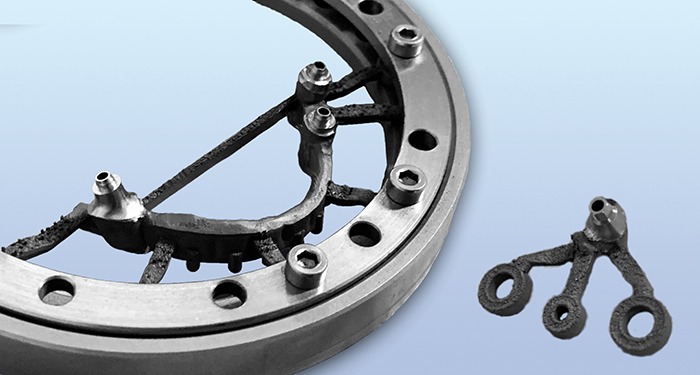

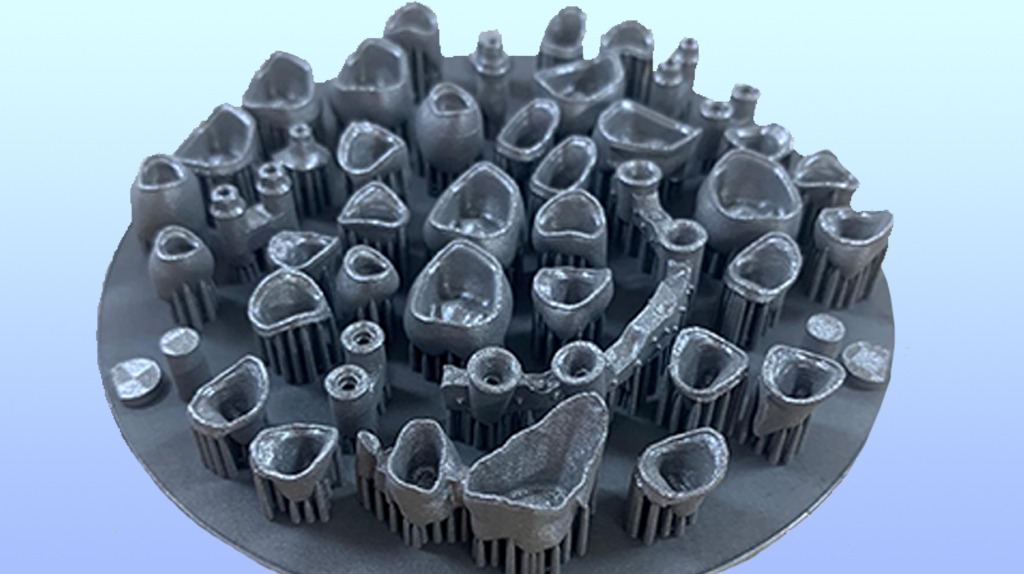

Simple calibration procedure and support insertion. Easily remove and reposition support equipment.

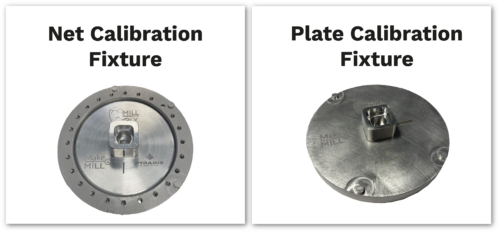

To ensure opertators maintain accurate results over time, CIMsystem has developed a dedicated fixture that is able to check and recalibrate the machine at any time. This support is available in two different models: one for the plate and one for the net.

MAIN BENEFITS OF USING CALIBRATION FIXTURE

1. Verify job positioning is at the zero point using a mechanical tool. This reduces manual errors.

2. Get real time data on any discrepancy between the 3D printing (laser melting) and milling refining processes.