MAKE&MILL

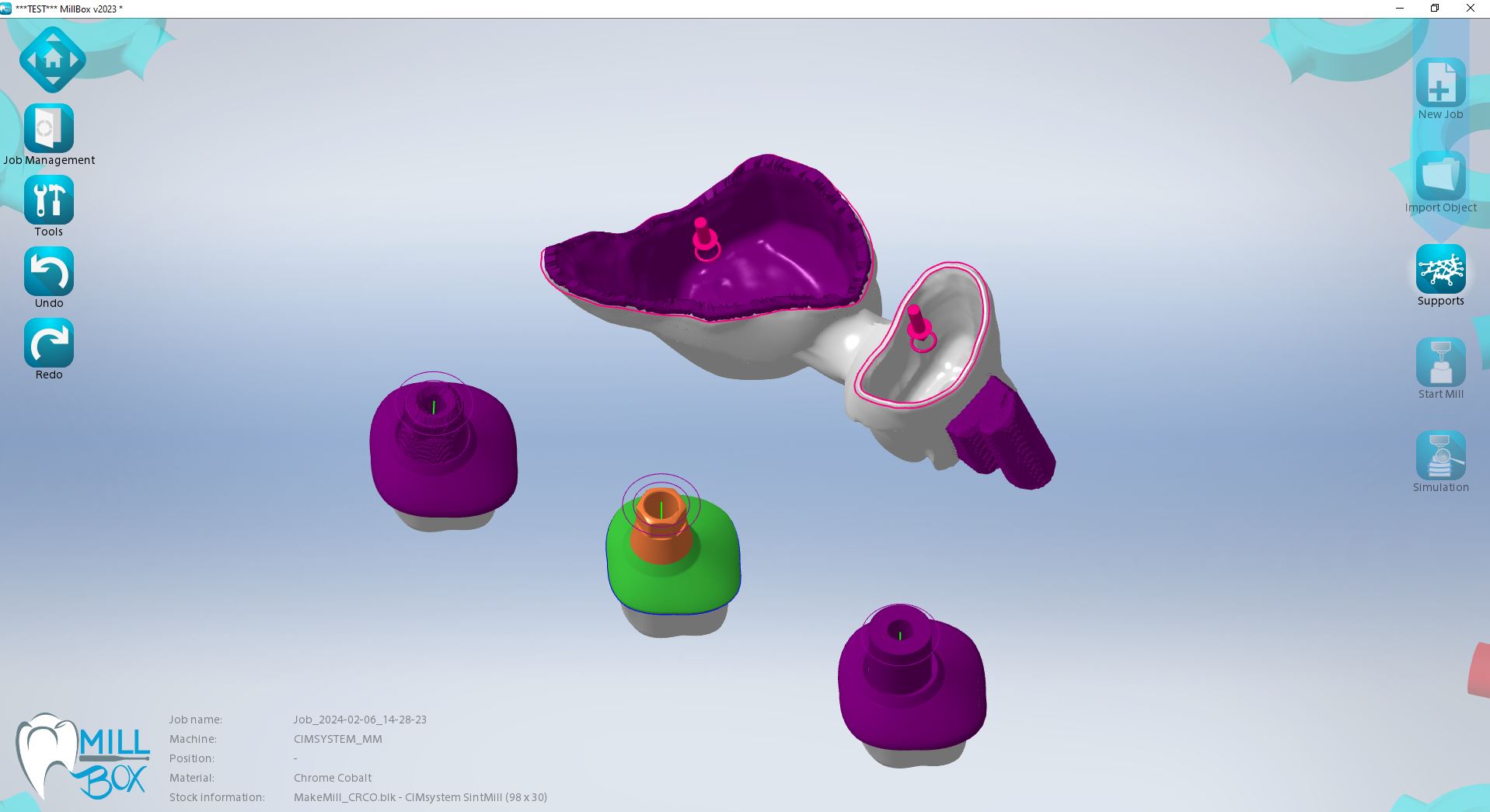

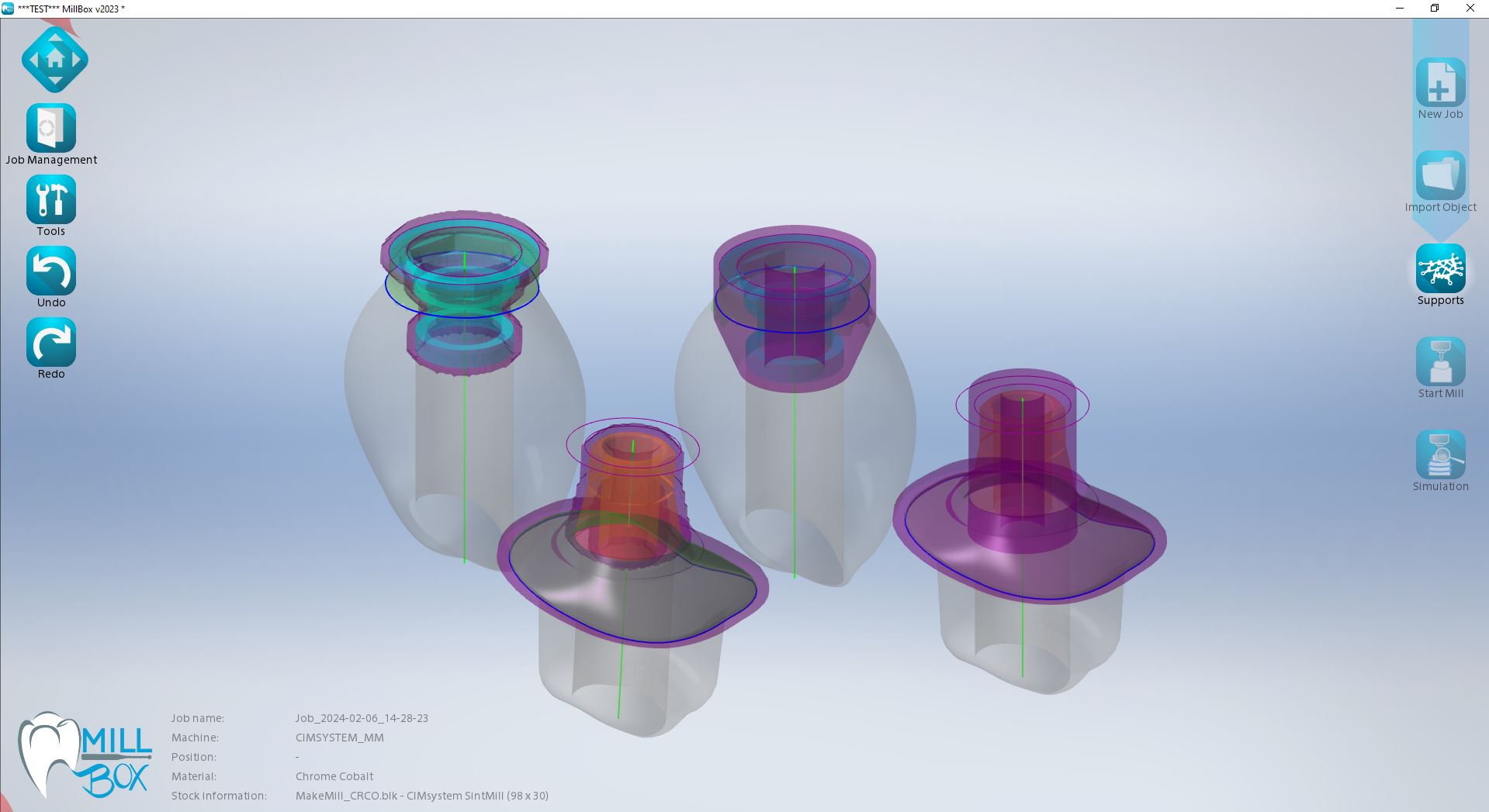

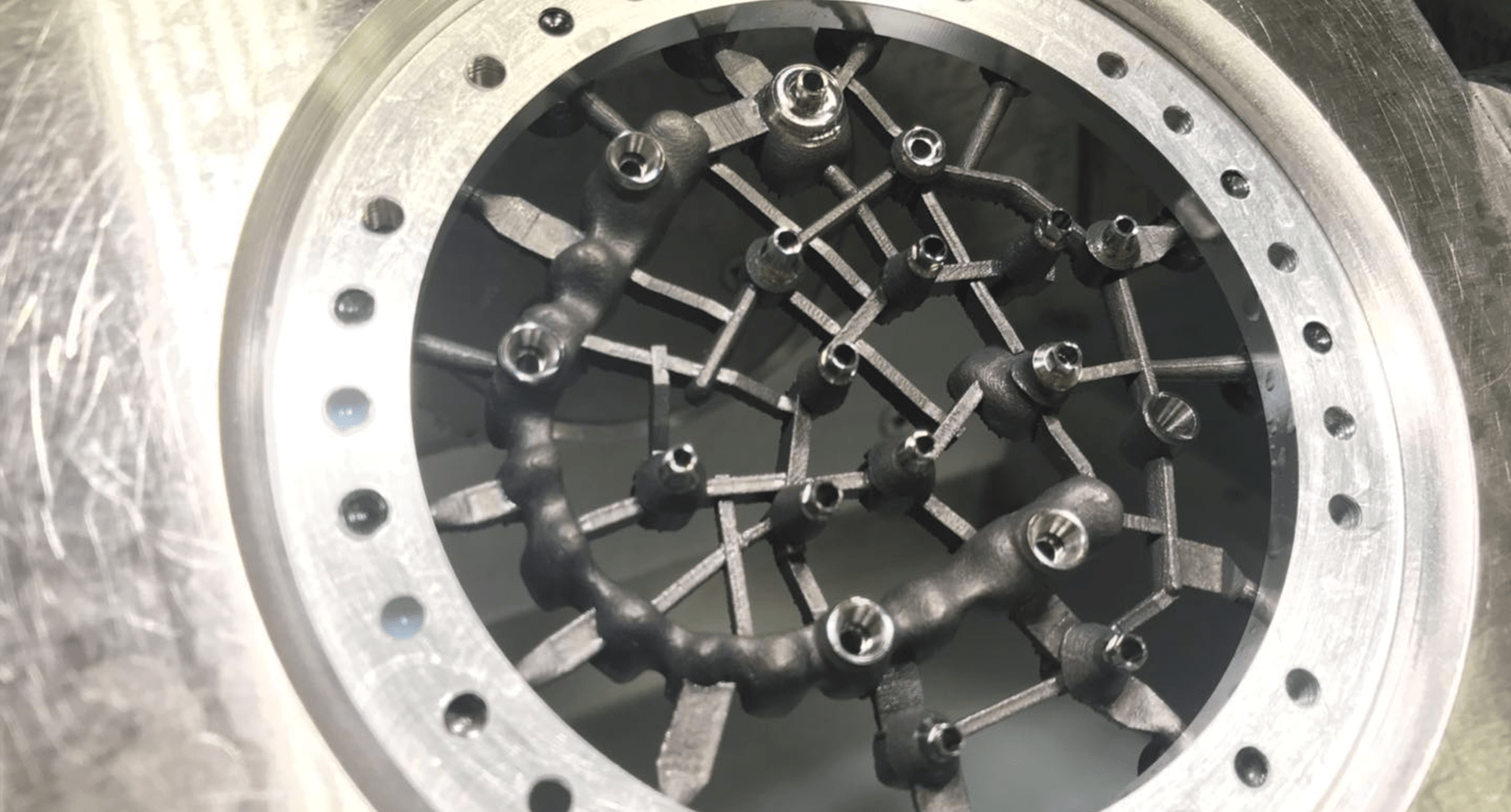

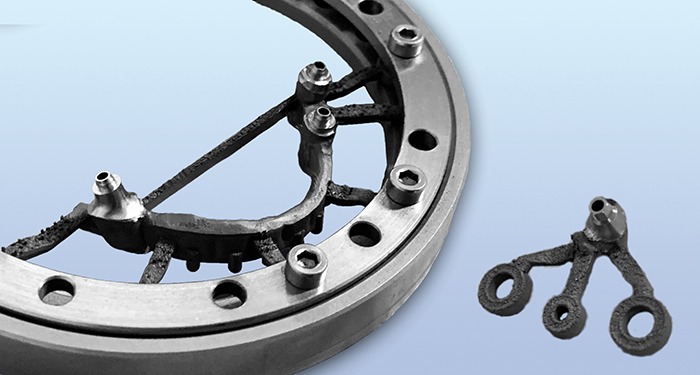

Dental CAM for milling and 3D printing

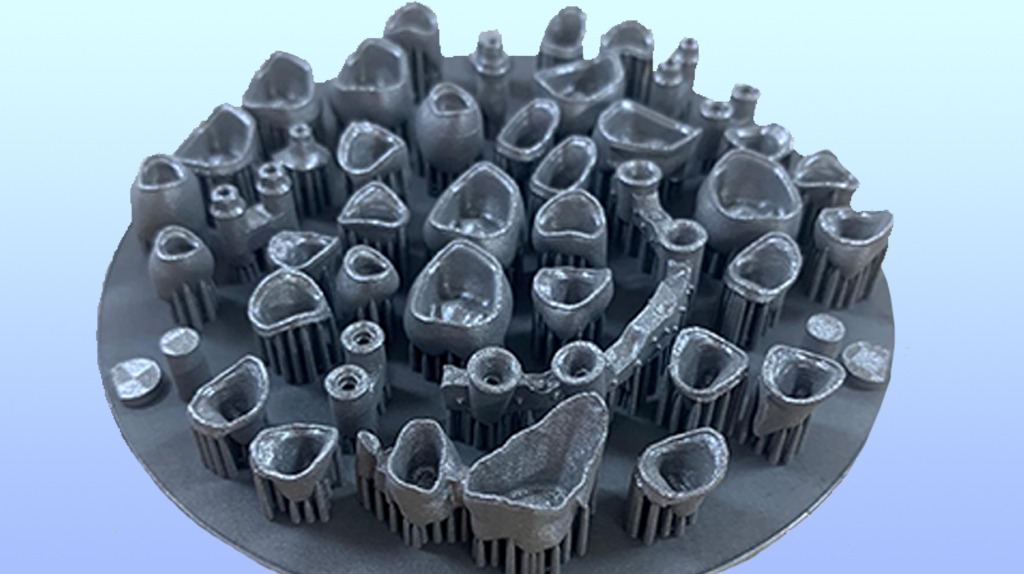

Make&Mill development generally coincides with MillBox, our premier Dental CAM software. Here are some specific features that primarily affect Make&Mill and enable the software to better perform its intended tasks.