MillBox News

MILLBOX

Dental CAM software for smart restorations

MillBox News.

2024

AUTOMATIC ROTATION FOR BITE RESTORATION TYPES

2023

“FAVOURITE ITEMS” FUNCTION

2022

NEW O’RING ROUGHING AND FINISHING OPTIONS – STRATEGY EDITOR

2021

FINISHING CAVITY ON NO CEMENT AREA

2020

PRE-MILLED ENGRAVING FUNCTION ADDED

2024

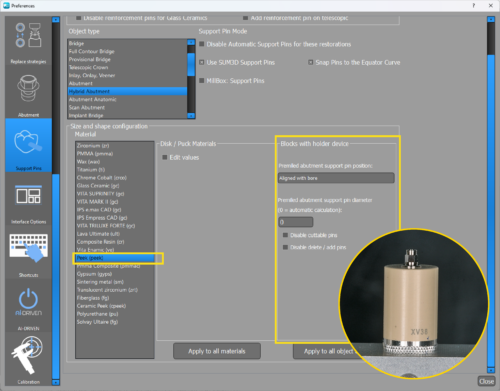

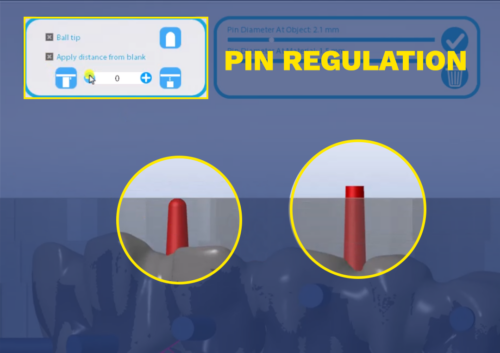

NEW SUPPORT PIN OPTIONS FOR PEEK PREMILLED ABUTMENTS

Users now have several options available to adjust various default support pin options for parts being nested in PEEK (material) premilled abutment blanks. Before this update it was not possible to manage support pin options for this material and object type. Enjoy!

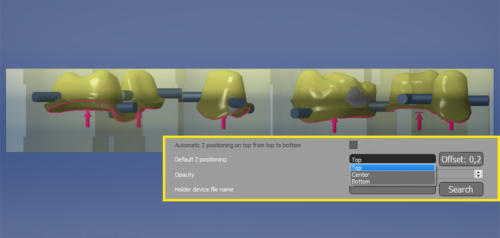

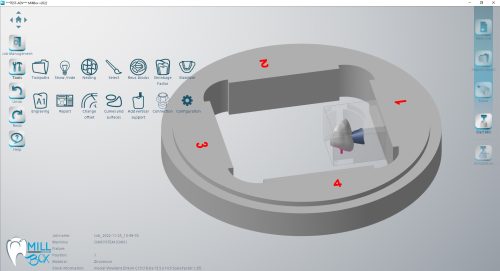

Z NESTING

Aimed at providing better management of the nesting operation in multi-layered blanks, this function allows operators to choose the Z nesting position for parts, providing options to nest parts near the top, bottom, or center of the blank. The selected position also includes a safety offset, which prevents the part from nesting outside the stock boundaries. Standard import is set to center positioning.

LOCATORS

New locator manual detection option has been added to simplify the milling procedure which can be performed all in one. It requires a strategy that manage locators (otherwise the function will show a warning and will not add the selection).

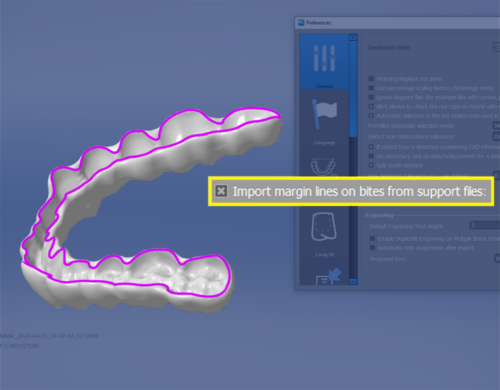

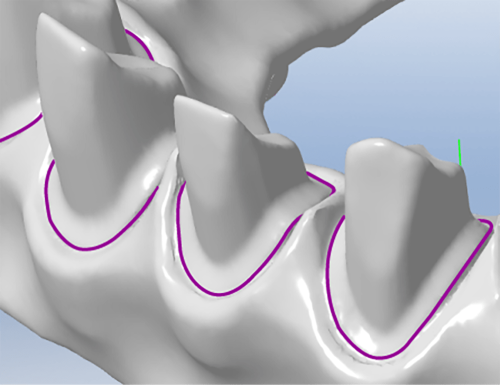

MARGIN LINES ON BITES

It is now possible to import curves on bite straight from the STL construction Info file. This function, which optimizes bite management, can be coupled with the bite orientation optimization option to streamline your work on bite restorations. If information about the margin line is not included into the constructionInfo file, it can be drawned manually.

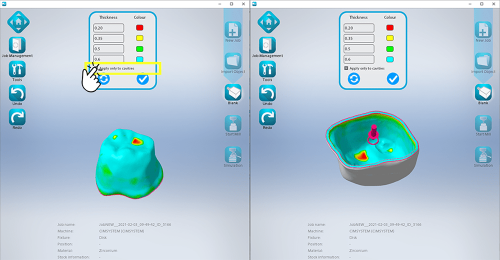

NEW DYNAMIC STL PREVIEW

The STL preview has now been improved! The existing dialog has a better layout and includes key operations toolbar to perform very important actions withing the preview dialog box itself such as the thickness analysis and restoration cut.

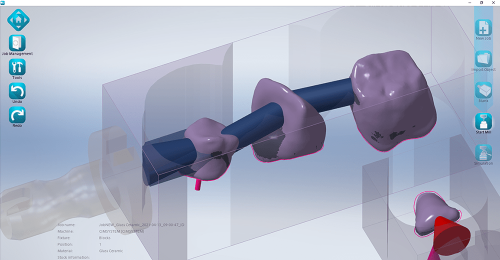

AUTOMATIC ROTATION FOR BITE RESTORATION TYPES

Regardless of the position in which the bite is imported from the CAD, MillBox is able to optimize its positioning on the support to make it immediately millable. This optimization is possible only if you activate the Artificial Intelligence options.

VERTICAL PIN SHAPE AND LENGHT

For sintering metal it’s now possible to change vertical pin shape and distance from top of the blank.

2023

EASY CONFIGURATION FOR “AI DRIVEN” FUNCTIONS

Do you need to manage MillBox automated functions? Now you can do it easily by accessing the configuration panel and switch them on/off with just one click.

NEW “QR CODE FUNCTION” FOR JOB REPORT

In the Job report Template you can now add a QR code containing the job report name to help you find it quicker when needed regardless the report page you have at your finger tips.

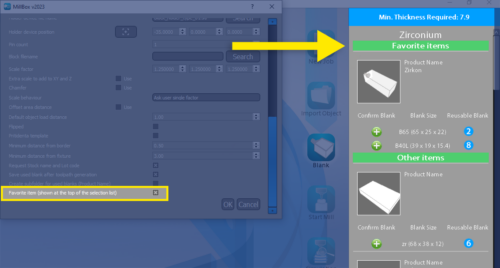

“FAVORITE ITEMS” FUNCTION

With this new feature you can now order your favorite items, on the bases of usage frequency; so you can save time and optimize your work.

CHANGE .BLK PROPERTIES

Now it’s possible to change the material and pallet code assigned to .blk file even if the milling parameters are already set.

ICON TO OPEN CNC FILES FOLDER

A new icon to access the cnc files folder is now available at startup. There is no more need of choosing a machine or opening a project before accessing the cnc files. This will help you in setting operations.

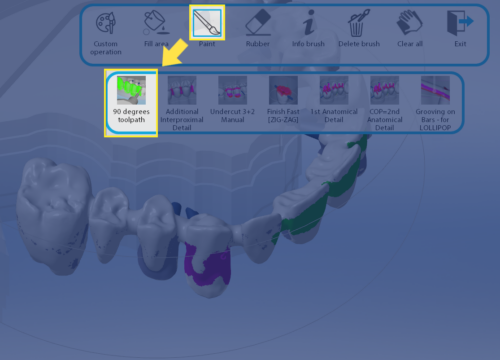

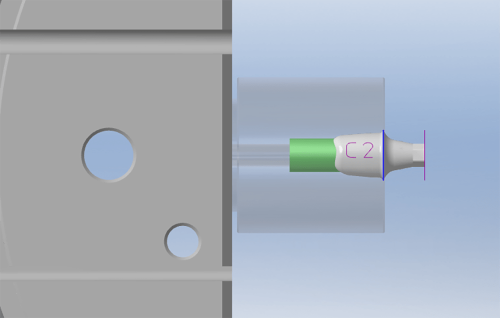

C.O.P. AND TOOLPATHS AT 90°

It is now possible to perform custom operations at the same time as 90° machining as well.

TOOTH OBJECT MENU

This feature change allows you to access key information like restoration thickness and cavity fit without the need of unlocking the restorations on the blank.

CHANGE MACHINE / TOOL-SET

From now on, you can not only change the machine for your milling but also the type of blank you will be machining on without restarting the nesting and calculation process.

FILEHUB

Available with 2023 MillBox new version, FileHub is an independent browser that helps you access all the STL files you have on your computer, gathering them into a single platform. FileHub is fully integrated with both MillBox milling software and the 3D printing solution Pyramis, providing you with an overview of all your open jobs at once. FileHub gives you the unique advantage to filter all your files according to specific parameters.

NEW SKINS INTERFACES

Play with MillBox background! Select a among four different skins and change the interface layout according to your daily preference. How? Click on Configuration Tab > Skin > Choose one. You can choose the following:

• Mist

• Purple

• Horizon (standard MillBox skin)

• Basalt.

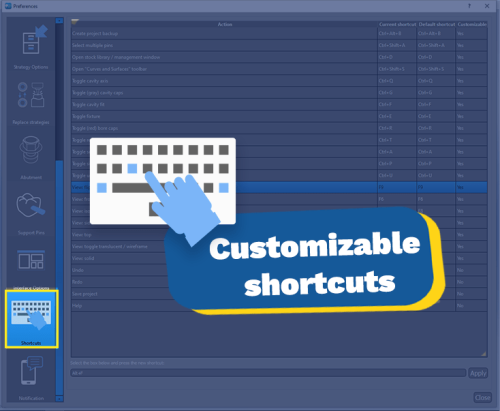

CUSTOMIZABLE SHORTCUTS

To customize the key sequence for most of the MillBox shortcuts a new “Shortcuts” tab to the configuration dialog has been added.

NEW SHORTCUT CTRL+ALT+B

To create a backup for support the new shortcut CTRL+ALT+B has been added.

2022

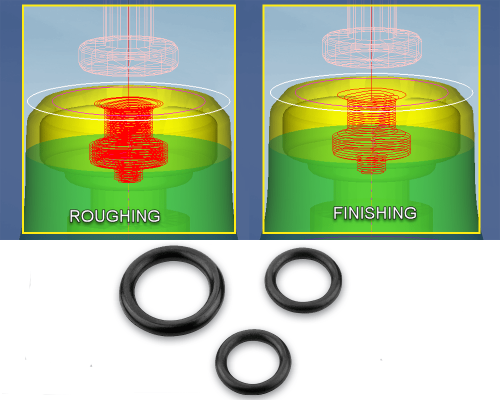

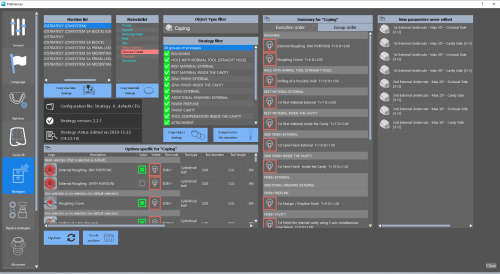

NEW O’RING ROUGHING AND FINISHING OPTIONS – STRATEGY EDITOR

No more manual operations for the o’ring positioning! With the new roughing and finishing options for O’ring the operator won’t need to manually create the o’ring space of insertion anymore. Upadate the strategy and gets all those improvements in a while!

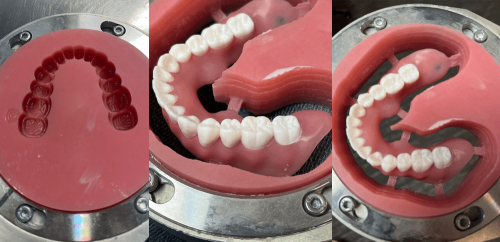

AUTOMATIC MOBILE DENTURE CREATION – STRATEGY EDITOR

The strategy now offers the chance of automatically roughing cavities pockets as first operation in 2 steps denture creation process. By using a strategy code that automatically breaks the CNC in two different slots, the operator will just need to manually fill the cavities with the appropriate material and wait for the CNC automatic launch for quicker and more reliable results.

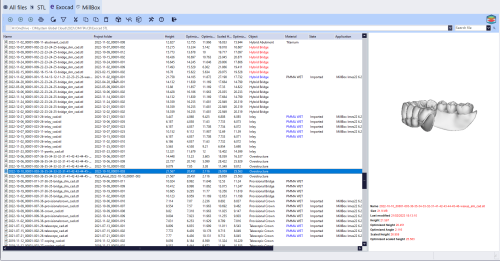

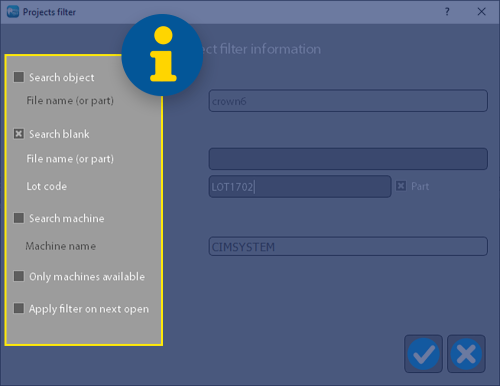

“RESEARCH PROJECT” FUNCTION

In the “research project” function now it’s possible to use the lot code as filter, furthermore the search now will consider all blanks in projects (in the case the project has more than one). This will save time and further improve the selection criteria for information.

“NEUTRAL OBJECT” FUNCTION

The “Neutral Object” function allows you to import .STL files with no analysis. After the import, the operator will manually proceed with the sole detection of the relevant curves and/or caps and launch calculations exclusively on the selected areas. This function is particularly relevant in the case of mixed or complex objects as it saves time by acting only on points of interest.

PIN MULTISELECTION

Pin multiselection is now available from the MillBox toolbar with the shortcut “CTRL+SHIFT+A”. Through the command, if there is no selection, the selection will be applied to all pins in the project, otherwise it will only be applied to the pins of the selected object. The function from the icon will ask how to apply the selection.

2021

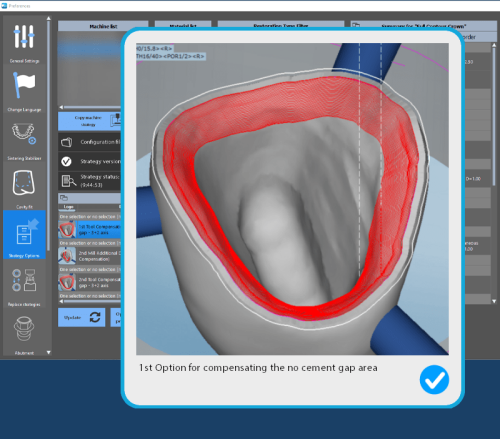

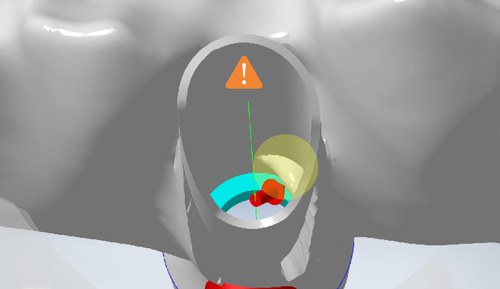

FINISHING CAVITY ON NO CEMENT AREA

In the CAD softwares during the design of the internal area, there is a possibility to set a region from the margin line without cement gap, being those surfaces in touch with the preparation. Depending on the preparation shape, the Ø1.0mm tool is not able to access all areas due to its size, leaving behind some small points with material and causing a non-perfect fit. New operations have been added under Tool Compensation Group in order to machine 1.5 mm distance from the margin line with a 3D Spiral 3+2 toolpath to be used with smaller tools like Ø0.6 mm or Ø0.3 mm to improve the fitting in those designs.

STRATEGY CONFIGURATOR

With the new strategy editor you’ll be able to create and customize your strategies quickly and easily. You can duplicate predefined strategies or create new ones according to your needs. Strategies will be updated every time you update the software, giving you the best at a click.

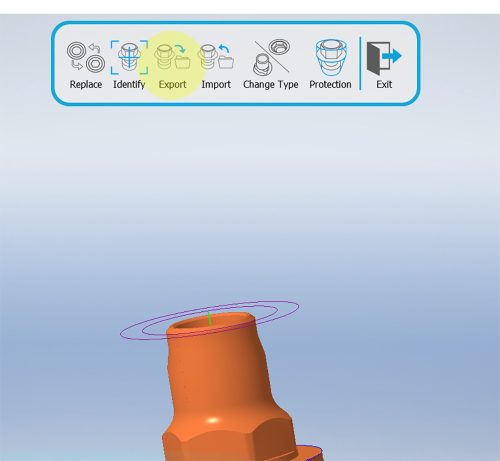

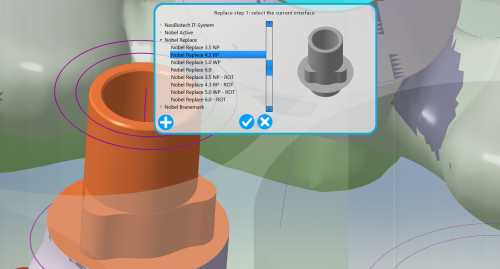

IMPLANT INTERFACE EXTRACTION

The feature enables you to extract an interface from a new implant and import into the replace library. The new interface will be saved into the software memory and you will be able to reuse once needed.

REPLACE FUNCTION

With MillBox you can automatically or manually replace an implant interface directly during the milling process. You can count on pre-determinate as well as fully customizable libraries and easily link those to the appropriate cutting strategy.

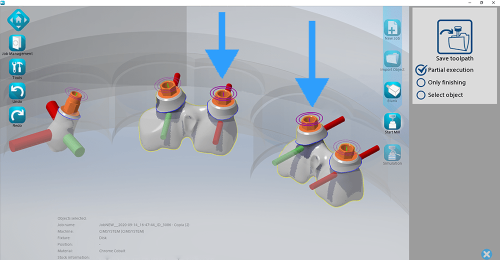

PARTIAL EXECUTION

Finally, you can select specific areas to refine any of your objects. Perfect for implant editing, this function can be use also for simple abutments and gives you the benefit of unprecedent time saving. No need of restarting the project, just edit what you need.

REMOVE HOLE OBSTRUCTION

In some case object imported have errors on the mesh which can cause failure in milling. Using MillBox you can easily detect this condition and quickly change the mesh to perform the mill correctly.

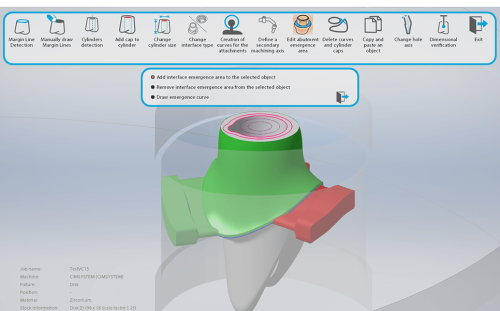

EMERGENCY DETECTION AREA

This improved function allows to detect the emergency area even if the base is not flat. This extends your operational range even to the imperfect objects and minimize the risks of milling errors.

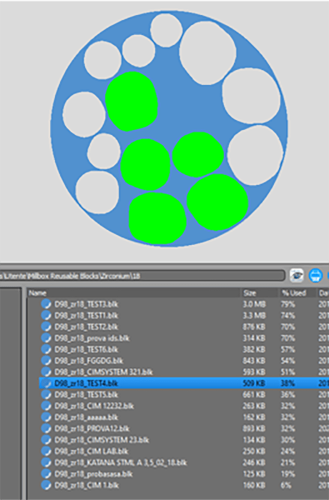

AUTOMATIC SELECTION OF USED BLANKS

The Artificial intelligence technology allows the software to automatically select and positioning the most used blank your object fits in, so that you can reduce material consumption and optimize your stock.

THICKNESS ANALYSIS

The software allows you to analyse the object quality before starting the milling and the restoration process. The thickness calculation is available on cavity or on the complete object mesh and can be applied to any object type. Now you can avoid starting a manufacturing process risking an object breaking.

OPTIMIZATION OF GLASSCERAMIC BLANK

Now it’s possible to insert more objects in a single GlassCeramic blank, objects will be merged before calculation in a single object.

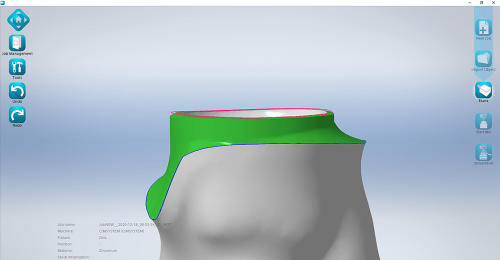

MANAGE OF ABUTMENT MARGIN

On abutment bridges now the margin of abutments defined on occlusal side are managed. The import of margin lines for abutment bridges and other object types that manage them must be enabled with the proper checkbox on configuration.

2020

PRE-MILLED ENGRAVING FUNCTION ADDED

Now you can recognize the worked object by the “premilled” using the engraving function.

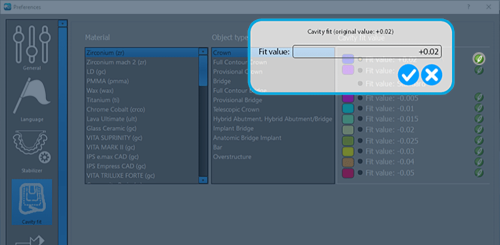

CUSTOMIZED VALUE ASSIGNMENTS FOR CAVITY

With the automation available in MillBox, it’s now possible to assign a custom value to the cavity table and obtain a more detailed level thanks to the colors. The assigned values will also be visible in eventual back-ups and can be reused for an in-depth check of the assigned values.

IMPROVED THE ARROW OF THE CAVITY AXIS

The arrow indicating the axis of the cavity has been refined to better show and verify the insertion and reference direction.

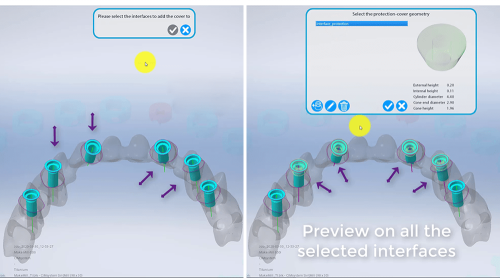

ADDED PROTECTION TO MULTIPLE INTERFACES

Protection has been added to multiple interfaces at the same time. The user can now use the same protection at multiple interfaces at the same time.

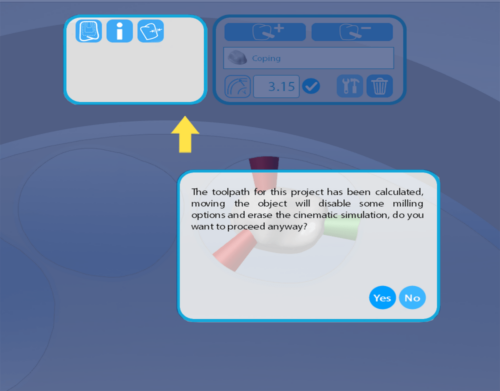

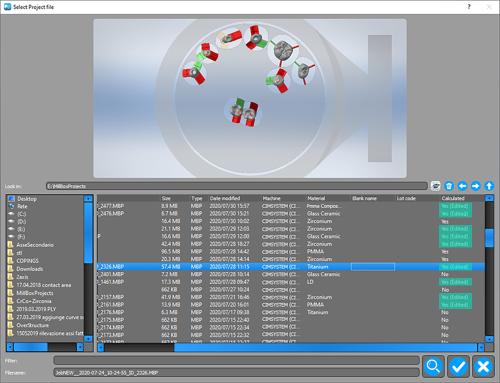

INFO ABOUT THE CALCULATION STATUS OF A PROJECT

For a better user experience of the software, the possibility of obtaining information on the calculation status of a project has been added. It will show “YES” if the project has been calculated and intact (without any post-calculation changes), but if changes have been made, the user will not see the simulation and calculation of the project.

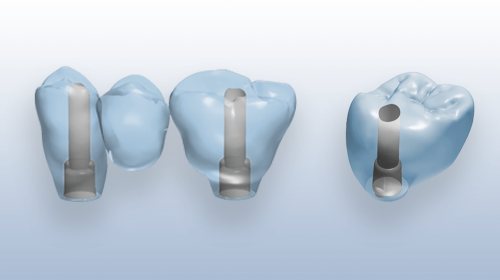

NEW RESTORATION TYPE: Anatomic Hybrid Abutment & Screw Retained Crown & Screw-Retained Bridge

This advanced function allows you to identify emergency areas even if they rest on a non-flat base. Thanks to this it is therefore possible to extend its operation to imperfect objects and minimize the risk of breakage.