News & Releases

News & Releases

Stay up to date with the latest features and releases of RhinoNC.

2024

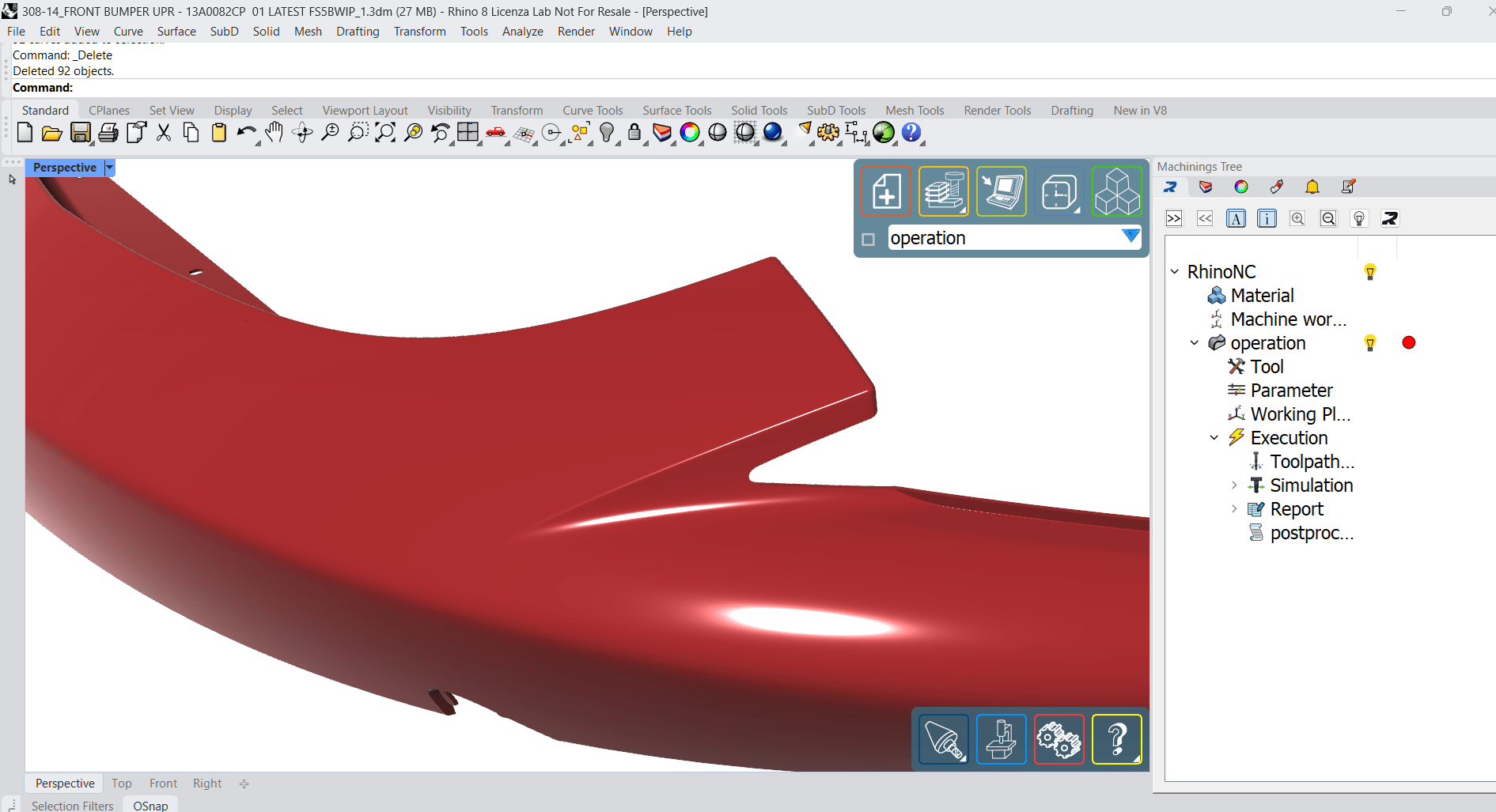

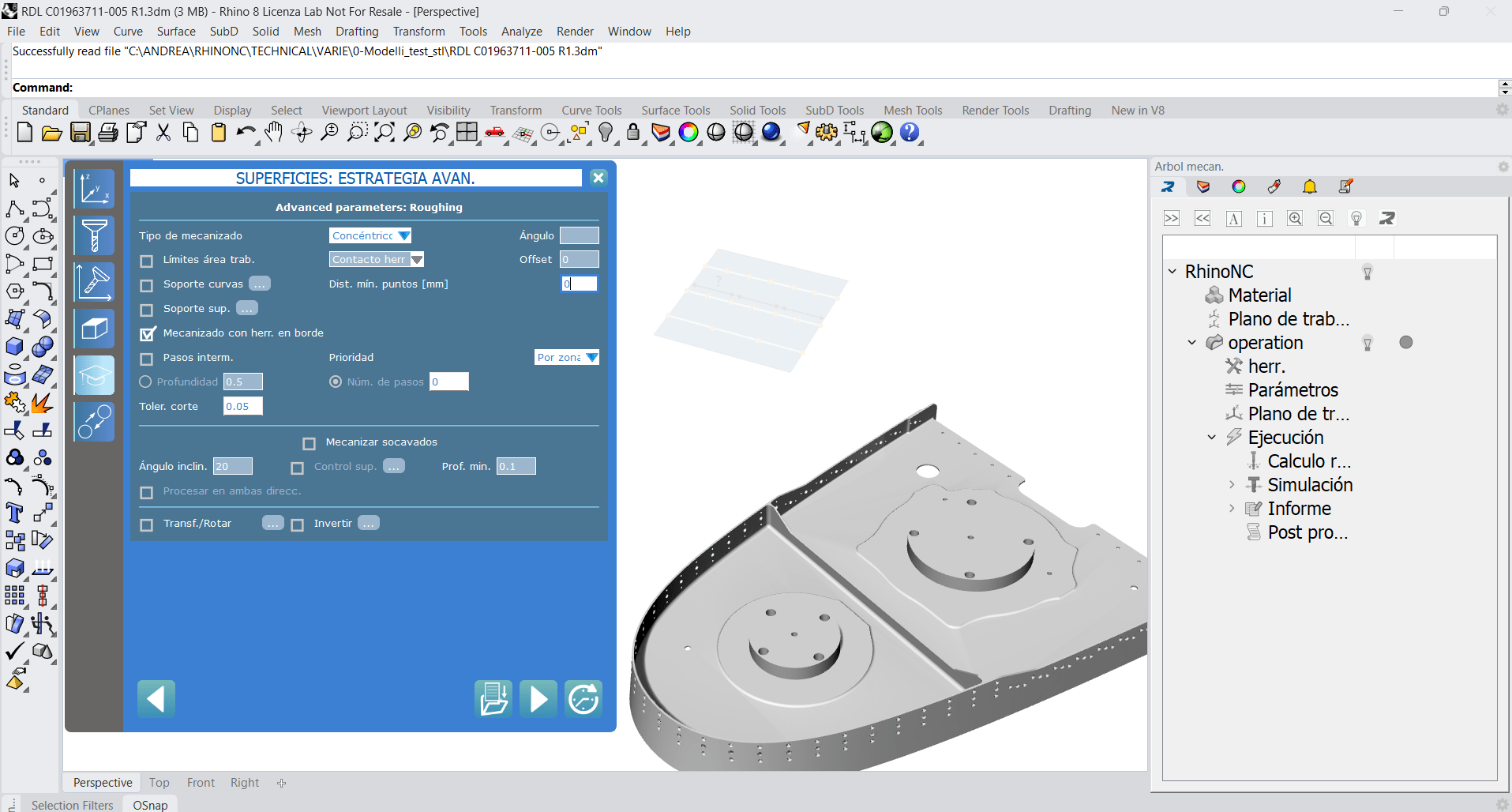

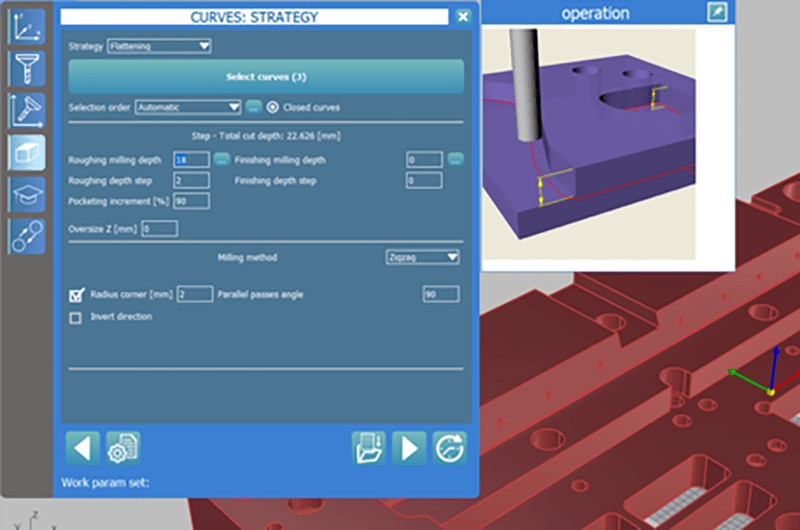

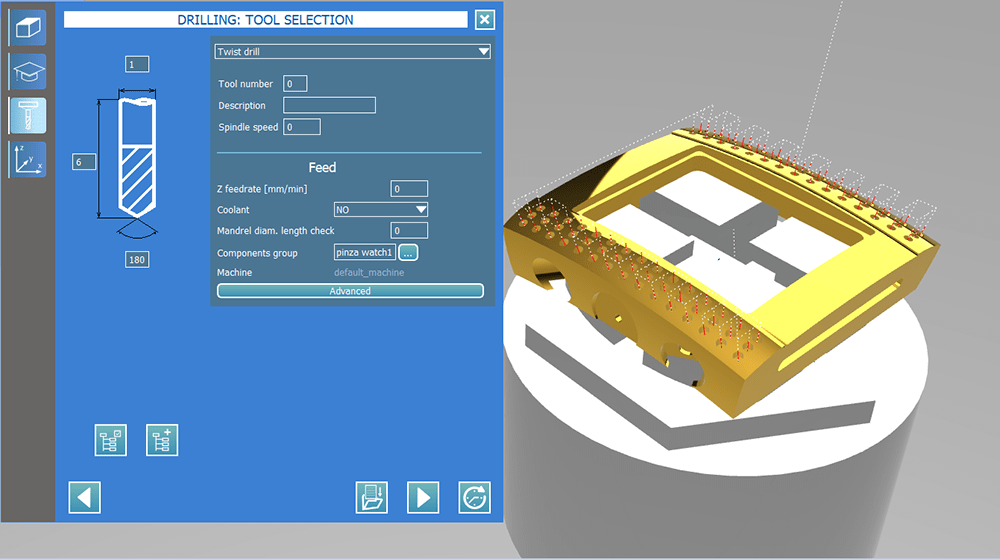

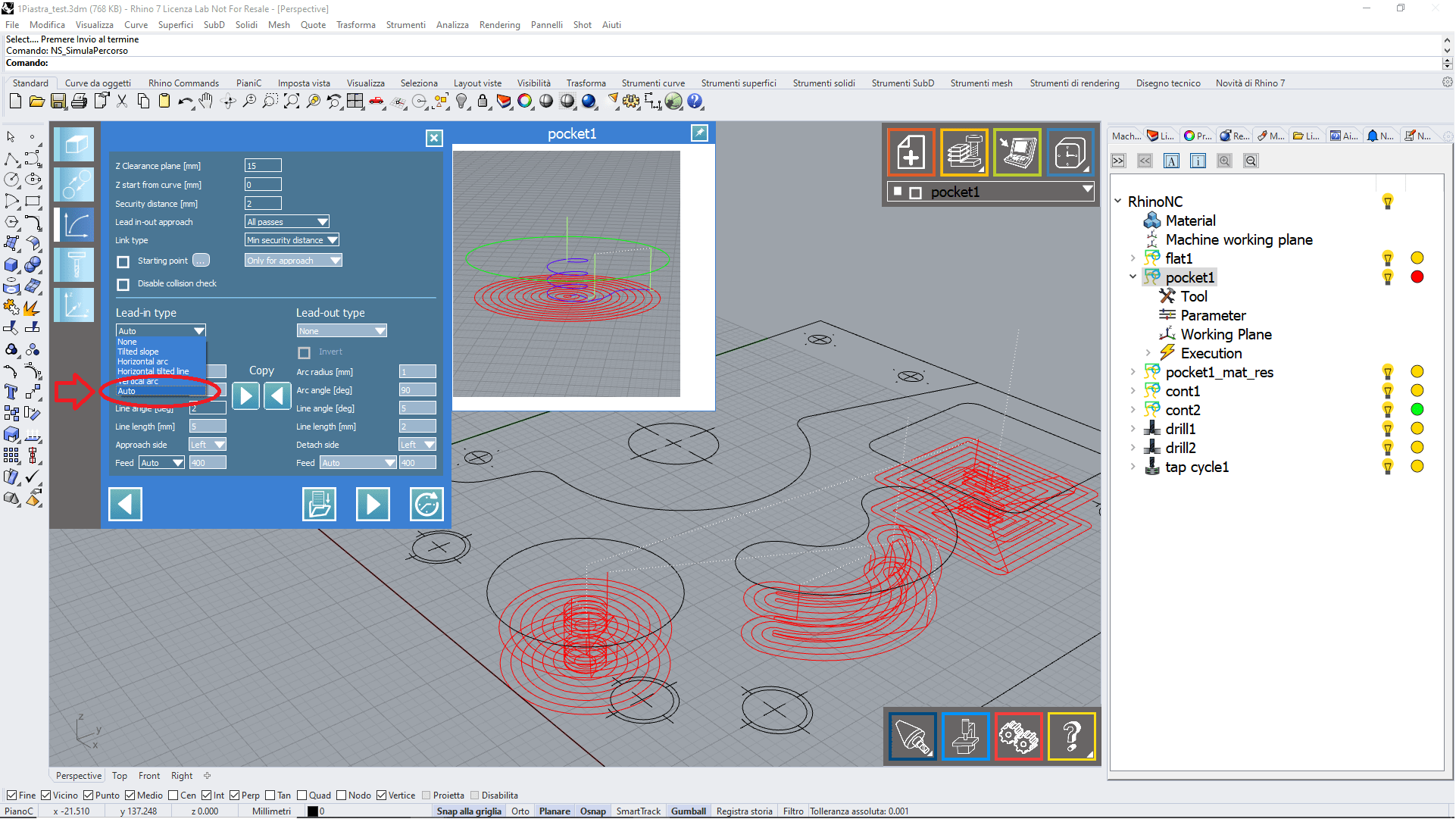

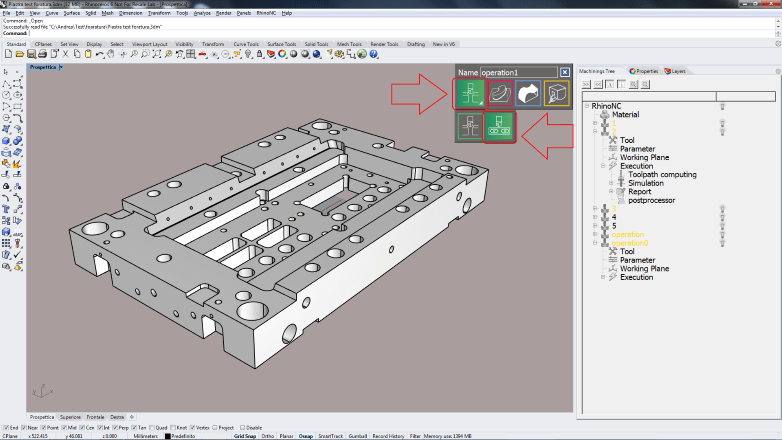

NEW WIZARD GRAPHICS

Graphics and some parameter settings have been changed in RhinoNC Wizard. Indeed, the parameters definition as well as the choice of the working options is now easier and more intuitive. Thus, let customers enjoy of a better workflow when creating the toolpath.

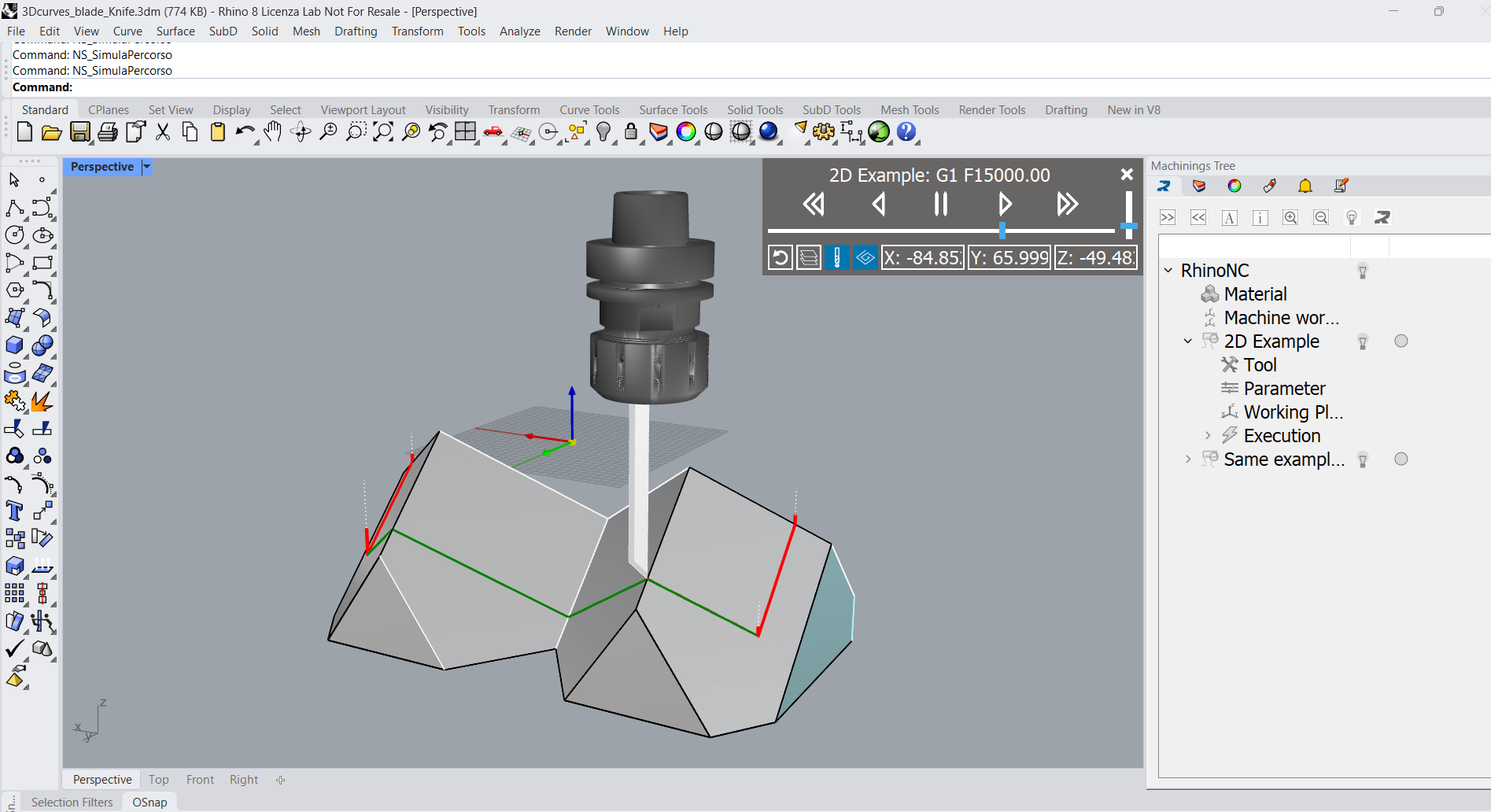

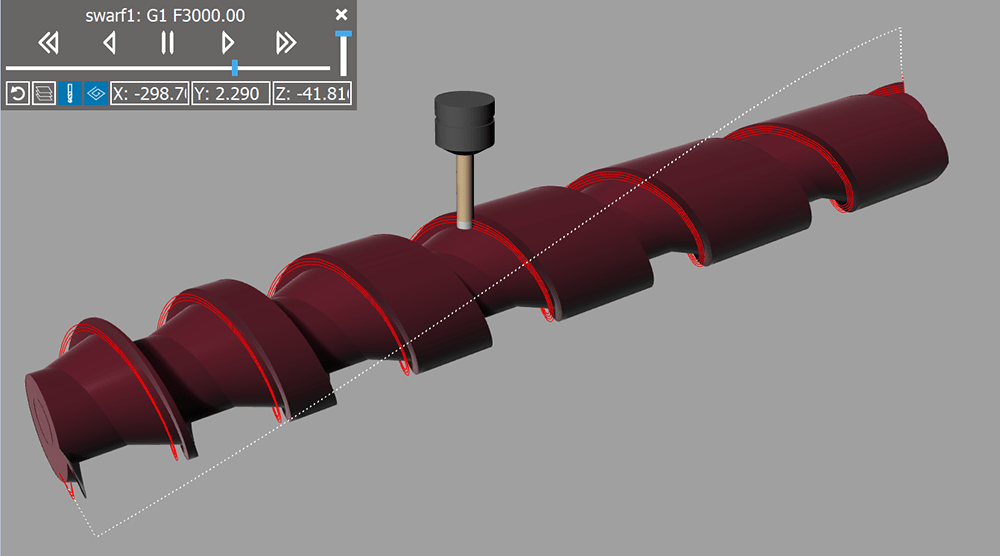

3D CURVES MANAGEMENT IN BLADE MACHINING

The curves management operation has now been improved thanks to the possibility of using both “knife” and “blade” tools in the blade machining strategy embedded in the curves management module. In addition to this, the possibility of operating approach and detachment with a 3D ramp has also been added to this machining.

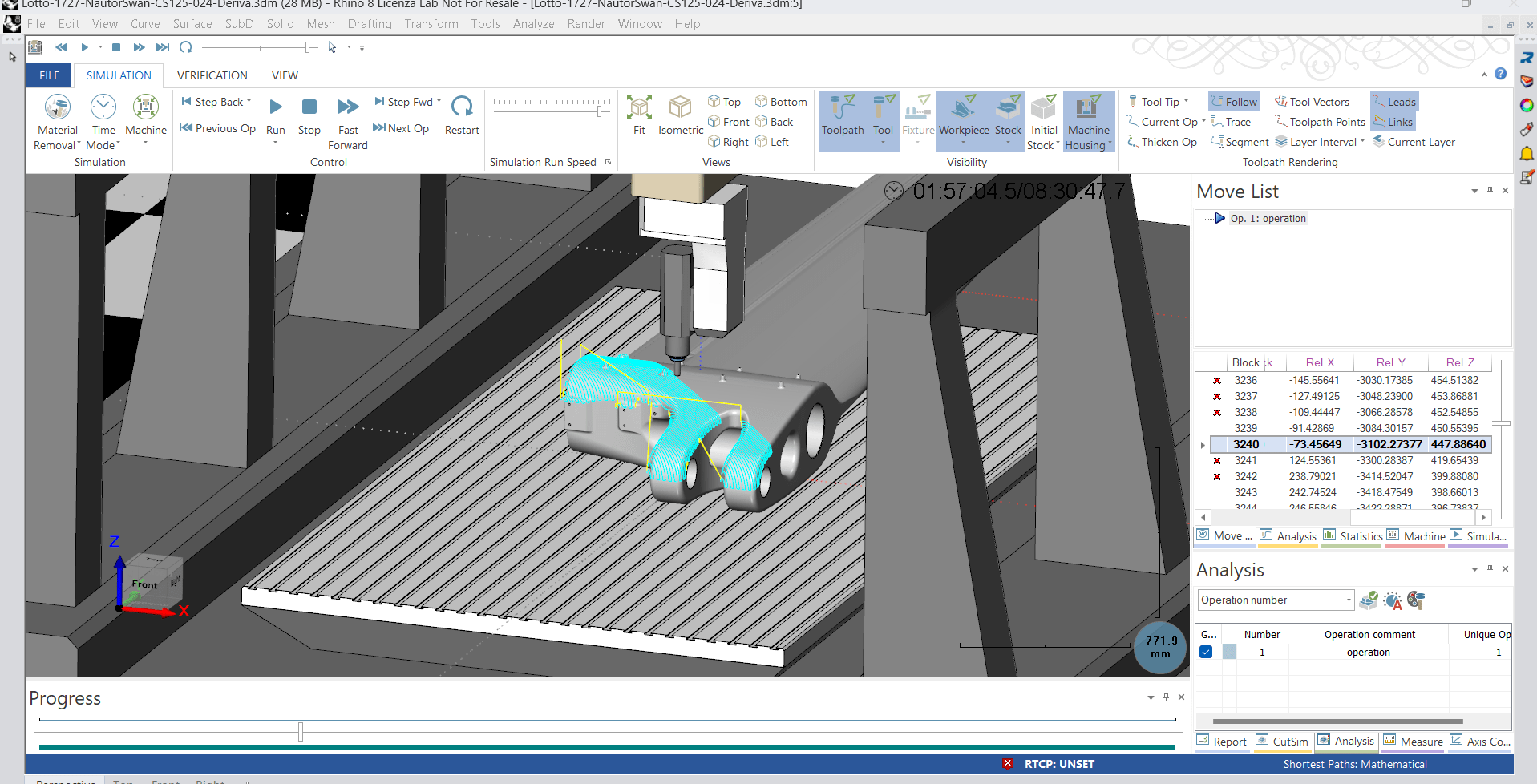

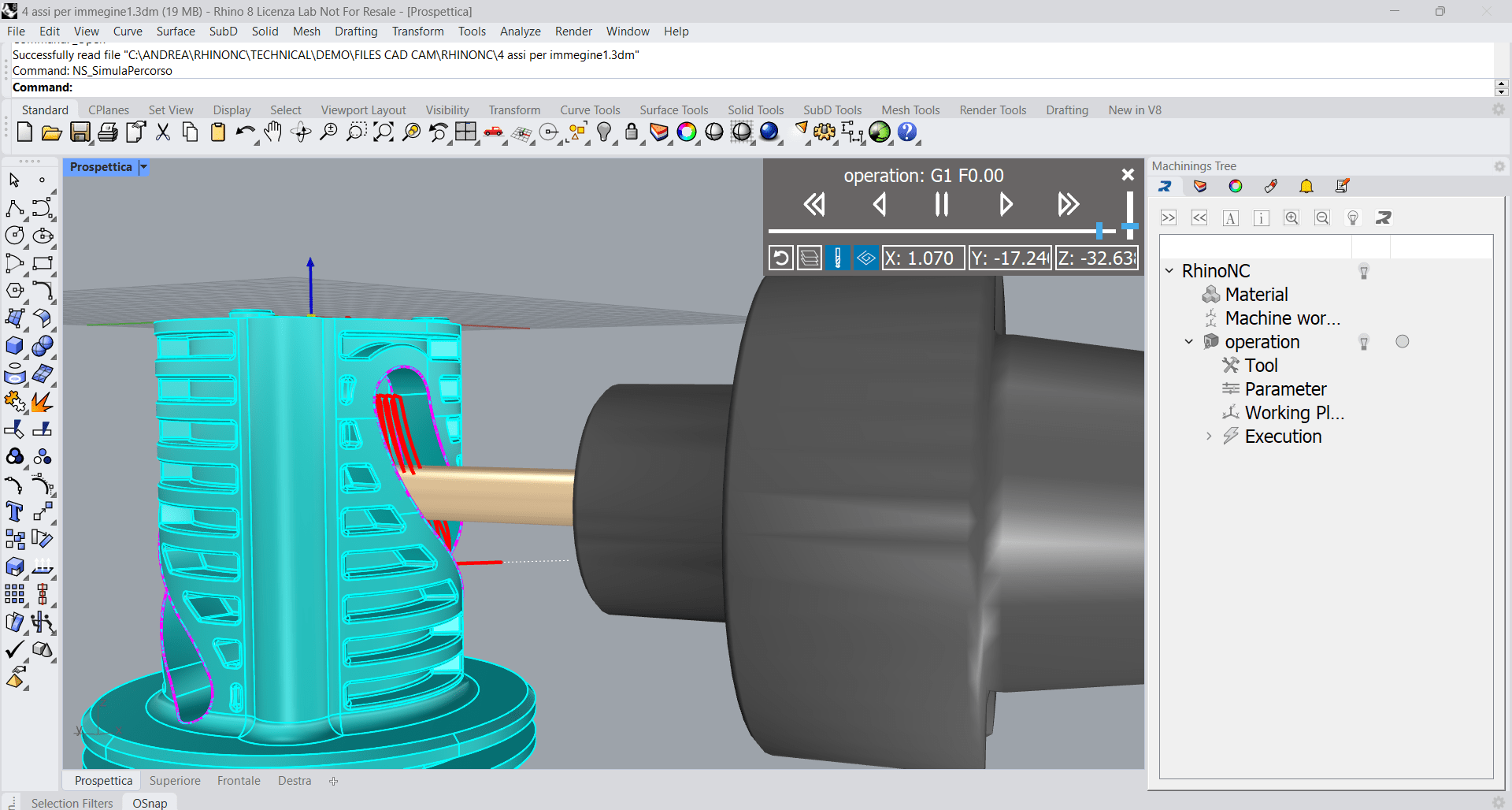

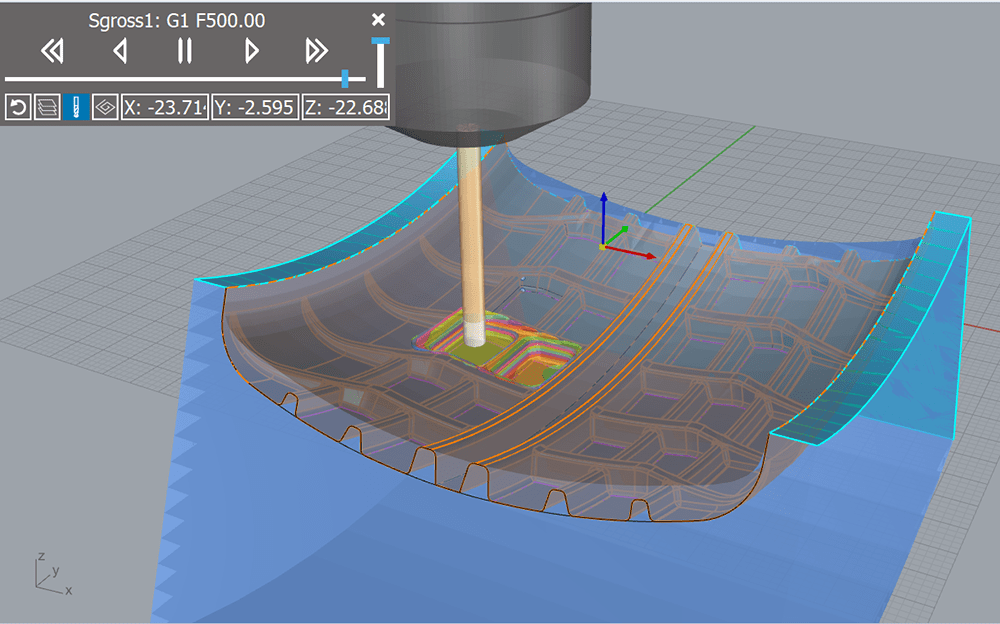

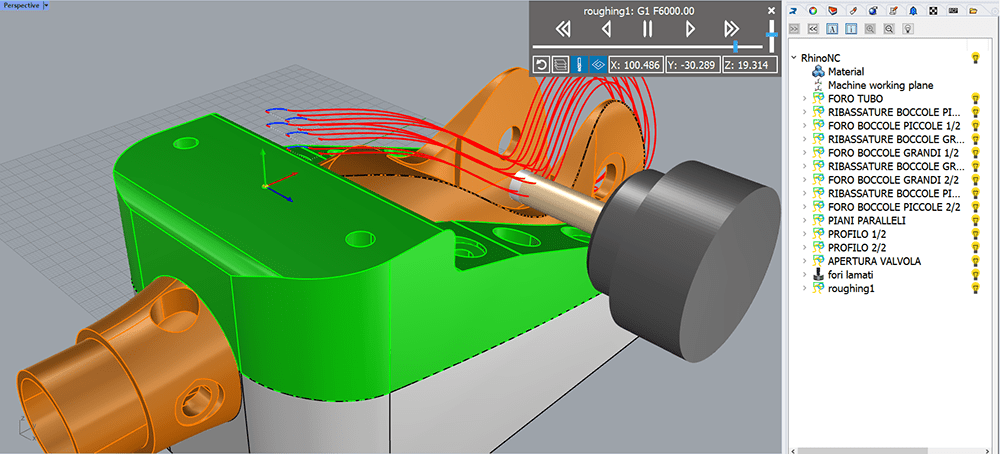

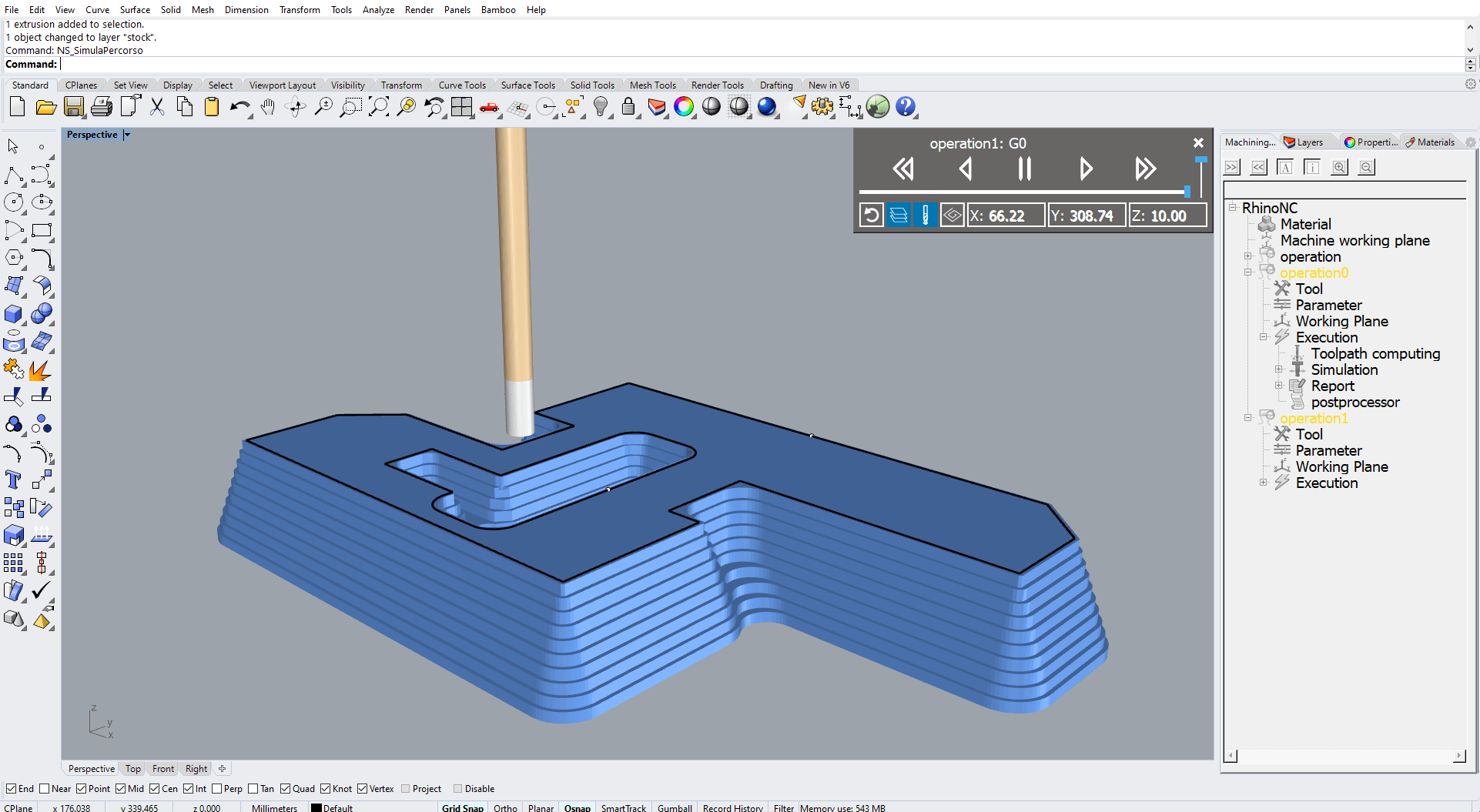

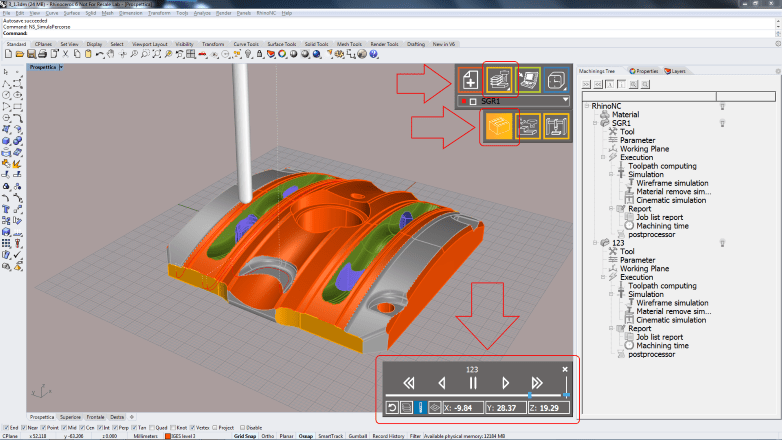

NEW KINEMATIC SIMULATION INTERFACE

The kinematic simulation interface has been changed. Now the simulation window is larger, and the Control Tabs are easier to see. Moreover, it is now possible to view the working coordinates related to the working panel as well as the machining tree to be simulated.

CONTAINMENT CURVES IN ROTARY MACHINING

The possibility of defining a working area through the selection of closed curves has been included in rotary machining.

2023

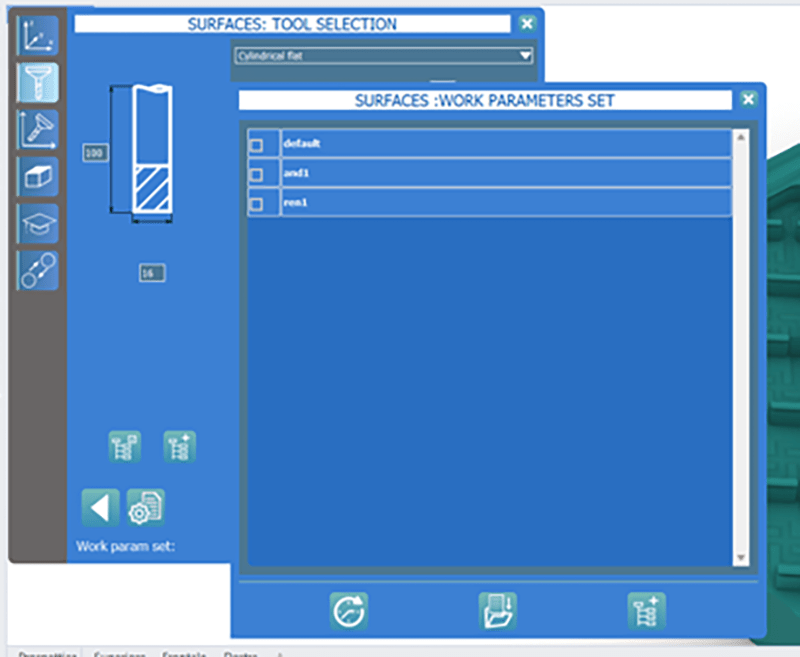

PARAMETERS CONFIGURATION

A new configuration module has been included that manages any parameter setups for each individual RhinoNC strategy; now the user can save the default values of the strategies in his own configuration, which can be recalled and modified whenever he wishes.

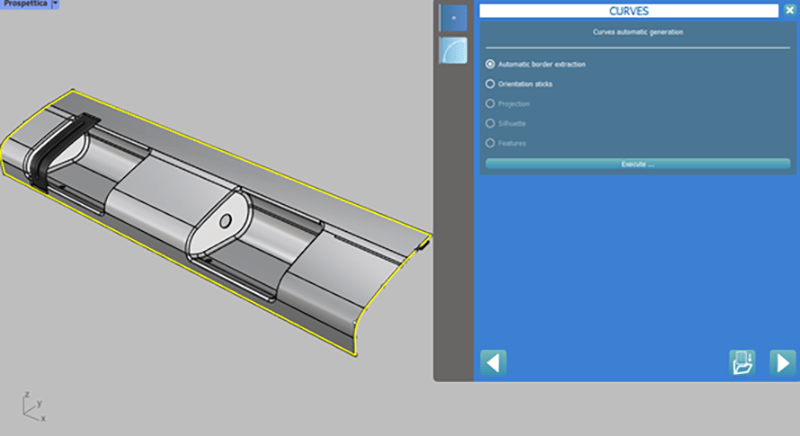

GEOMETRIC ELEMENTS CREATION

New geometry object creation commands have been included that improve the goodness of toolpaths. It is now possible, in fully automatic mode, to extract from 3D objects the edges of the geometry to be machined and create a single curve in continuity, using it as a work area or as a cutting line. It is also possible to create directional segments for tool orientation quickly and easily, or to make geometric points directly on the surfaces to be machined.

LASER MODULE

It has been added the module for machining related to machines with Laser technology; now you can create cutting or welding strategies with all the specific features for these machines, such as the possibility of inserting specific cutting speeds along the selected geometry or inserting special movements to make the tool path uniform. All this for machines with Laser technology, from 2 to 5 continuous axes.

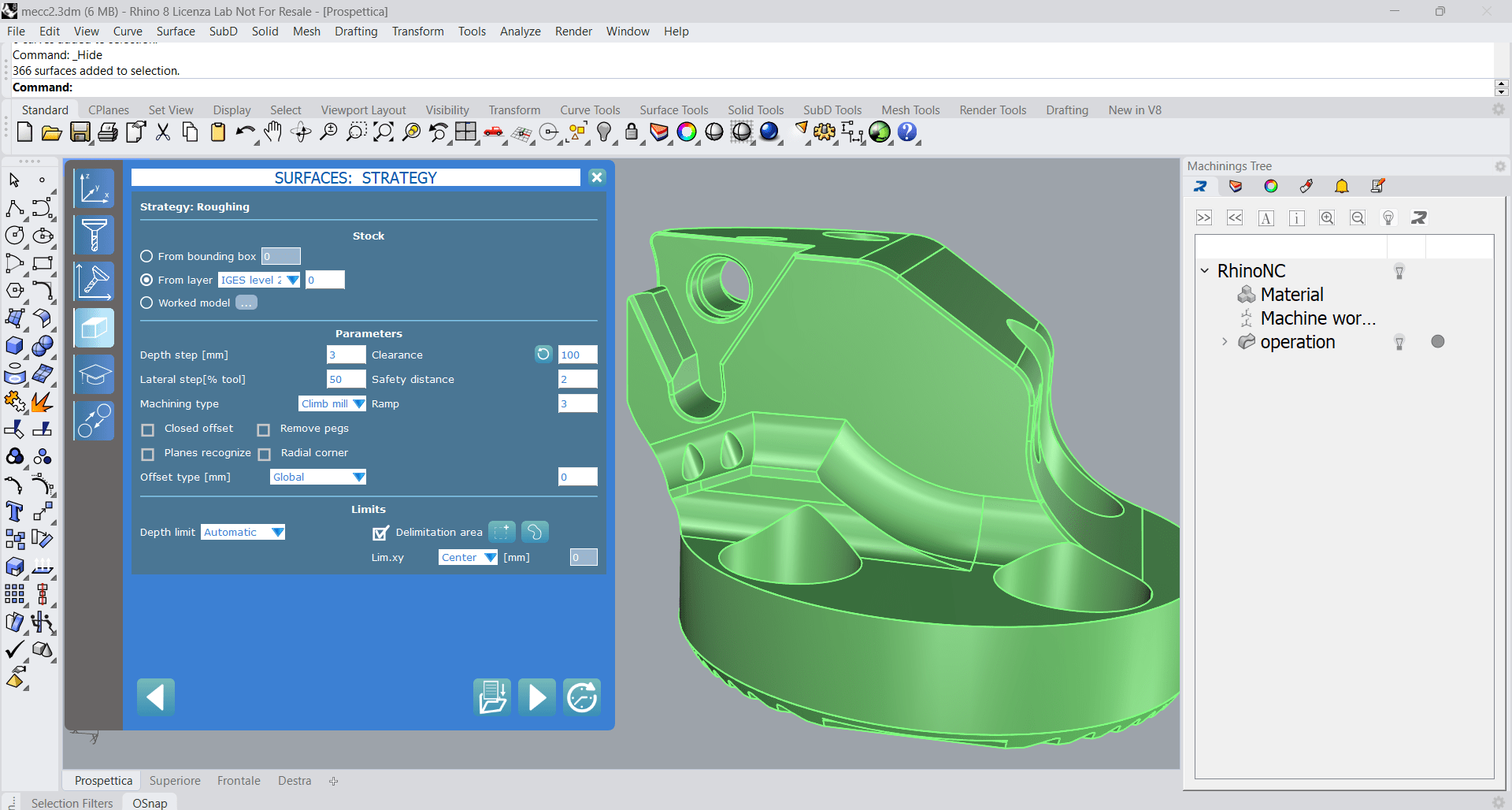

NEW WIZARD

Within the RhinoNC Wizard some very practical implementations have been included when creating machining strategies. Now you can see, for example, the number of geometric entities to be machined or used as boundaries; measurements of depths or distances to be machined are always referenced to the tool orientation, etc.

STAND ALONE INTERFACE

The Stand alone interface has been redesigned, making it even more user-friendly and easy to use. This layout version makes it possible to work with RhinoNC by highlighting only the CAM commands, so that those not using the CAD part will no longer have all the icons displayed, resulting in smoother toolpath creation.

NEW PRELOAD ANGLE AXIS

The possibility of changing the initial angle for a 4 – or 5-axis continuous machining operations has been added. This allows the full angular movement of the machine tool’s rotary axes to be utilized, avoiding the need of angle resetting or repositioning when calculating the tool path.

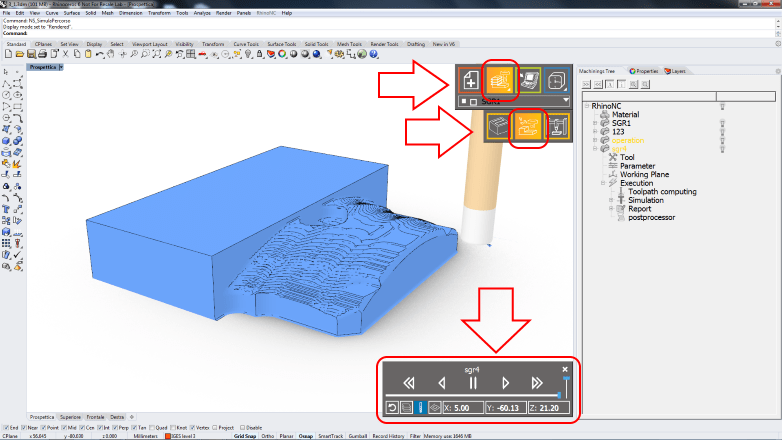

CHOICE OF QUALITY OF RESIDUAL MATERIAL FEATURE

The possibility of choosing the display quality of the simulation with residual material has been added. The new function allows for an optimal and precise simulation result, depending on the file size and the characteristics of the available hardware.

NEW OPENING FUNCTION AFTER CALCULATION

It is now possible to leave the machining wizard open after entering the machining parameters and launching the tool path calculation. The use of this function avoids the need of selecting again the strategy turning the process into a faster and simpler machining operation.

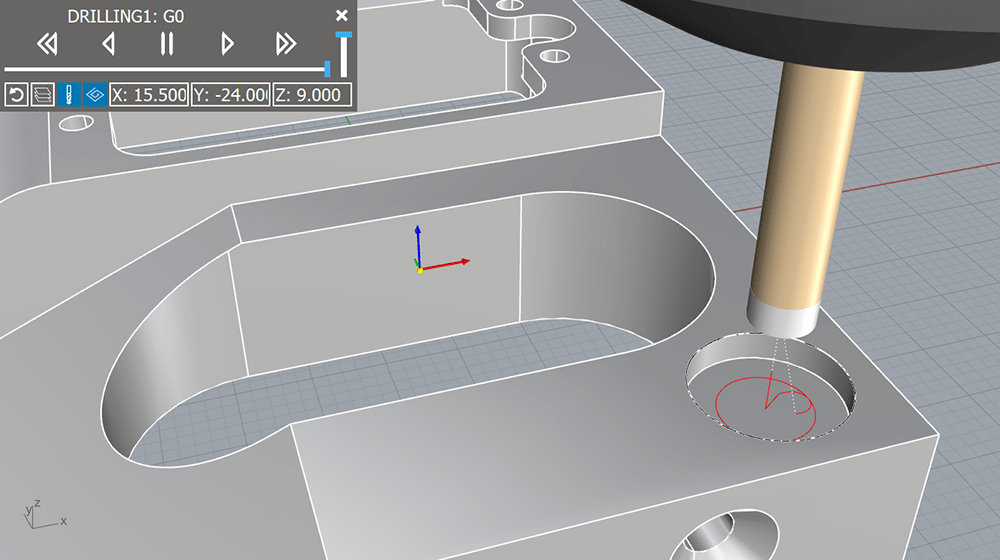

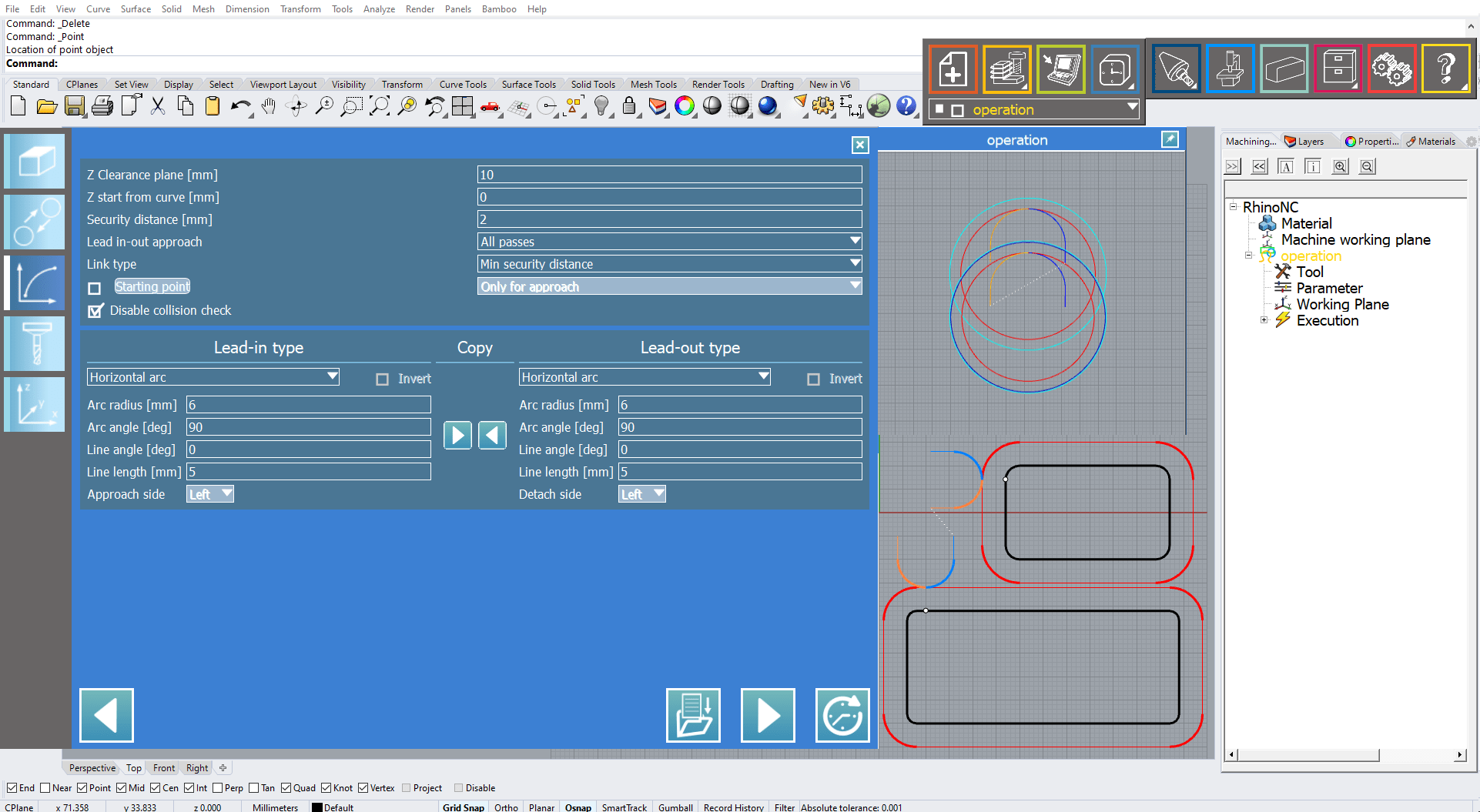

DRILLING APPROACH

The possibility of approaching the diameter of the hole to be machined with a circular attachment and detachment has been included in the drilling cycles, as ‘hole contouring’. This allows the tool to approach the geometry to be machined in a tangible way, creating a more regular and uniform tool path.

NEW GENERATION OF POSTPROCESSOR

A new generation of fully automated and customisable postprocessors is now available within version 2023 of RhinoNC.

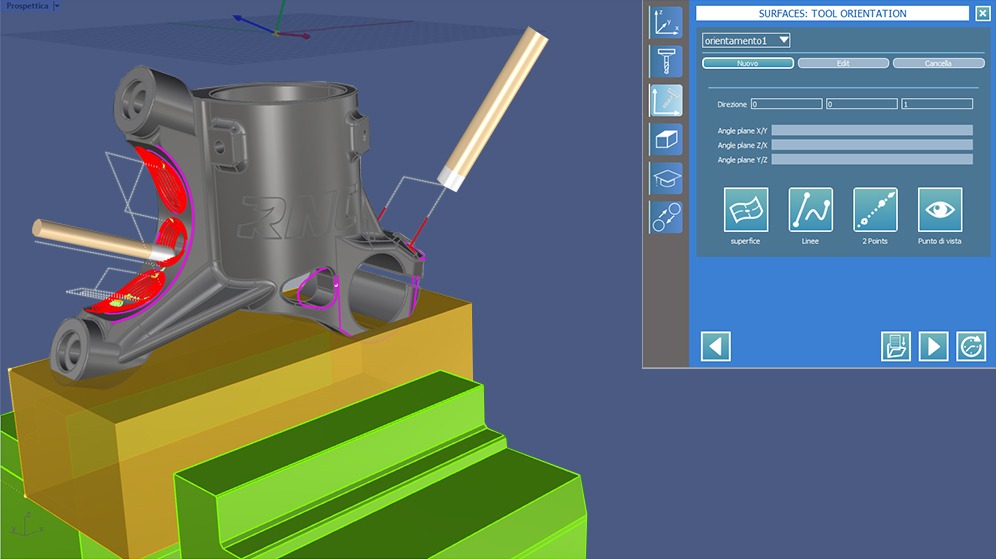

NEW TOOL ORIENTATION MANAGEMENT

It’s now available the new tool orientation management in machining strategies, for milling machines up to 5 axes or on anthropomorphic robots.

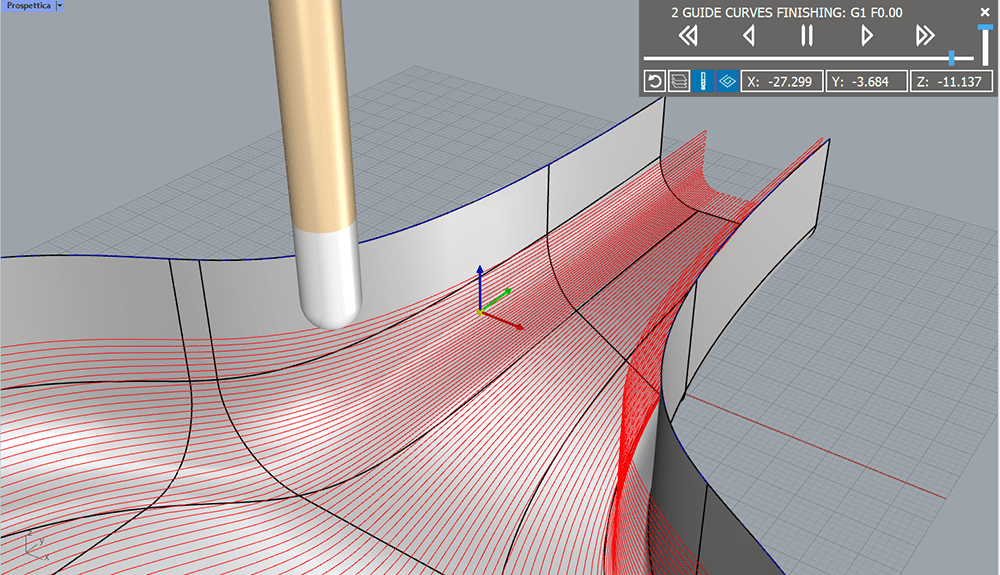

NEW GEODESIC STRATEGY ON 3D SURFACES

This new strategy of the ‘3D SURFACES’ module has been inserted to have a further possibility of finishing 3D objects. The geodesic strategy allows you to obtain refined tool paths by working with the edges or containment curves of the chosen work area; you can work for example between 2 guide lines, or by following automatically the surface dimensions of the object.

2022

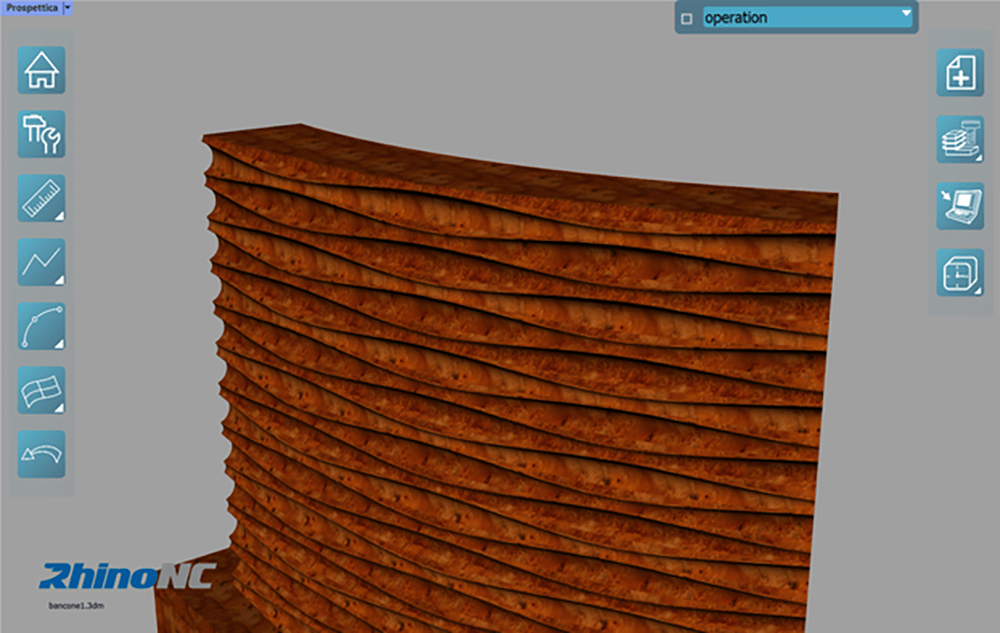

MULTIPLE CONTOUR MACHINING

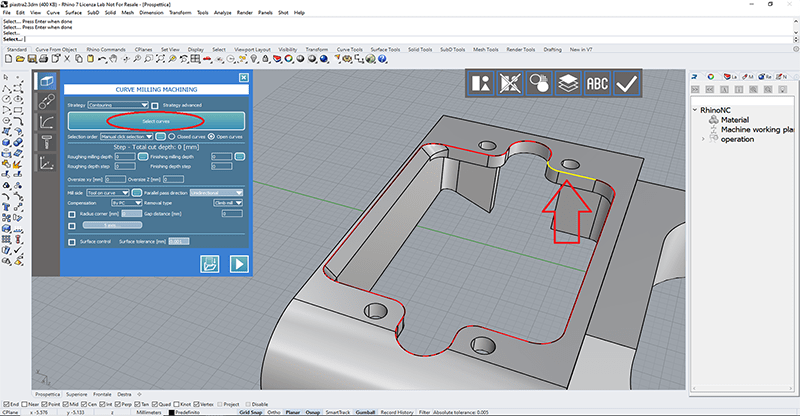

In the curve contouring strategy, the possibility of being able to machine three-dimensional curves with multiple lateral passes has been included; this allows three-dimensional objects that are characterized by large areas to be machined with small tools, and therefore with multiple passes.

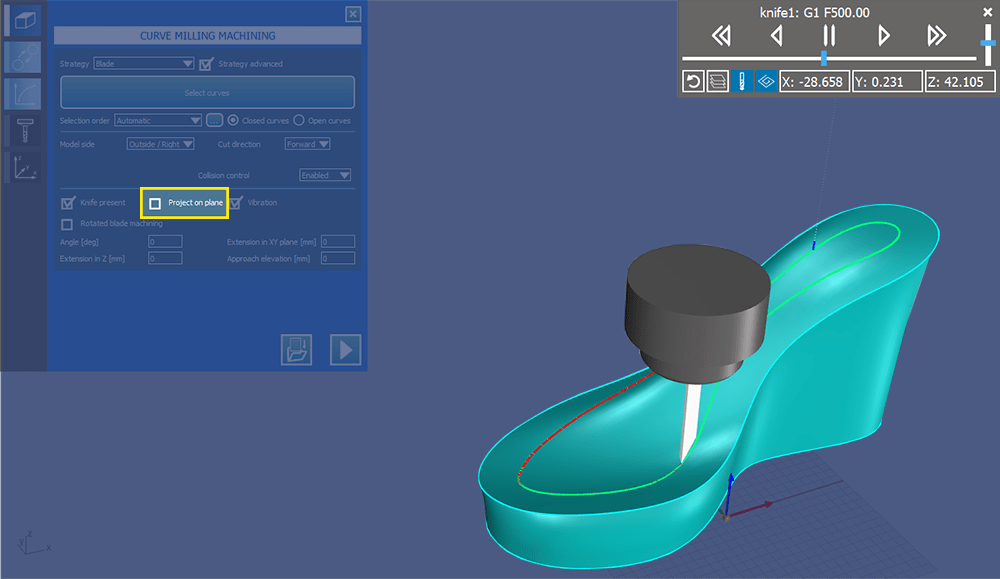

NEW 3D MACHINING WITH THE KNIFE TOOL

The cutting strategy using the ‘knife’ tool was limited to 2D geometries so far. From now on this new function is extended to the possibility of cutting 3D curves in the space, thus handling all different types of work.

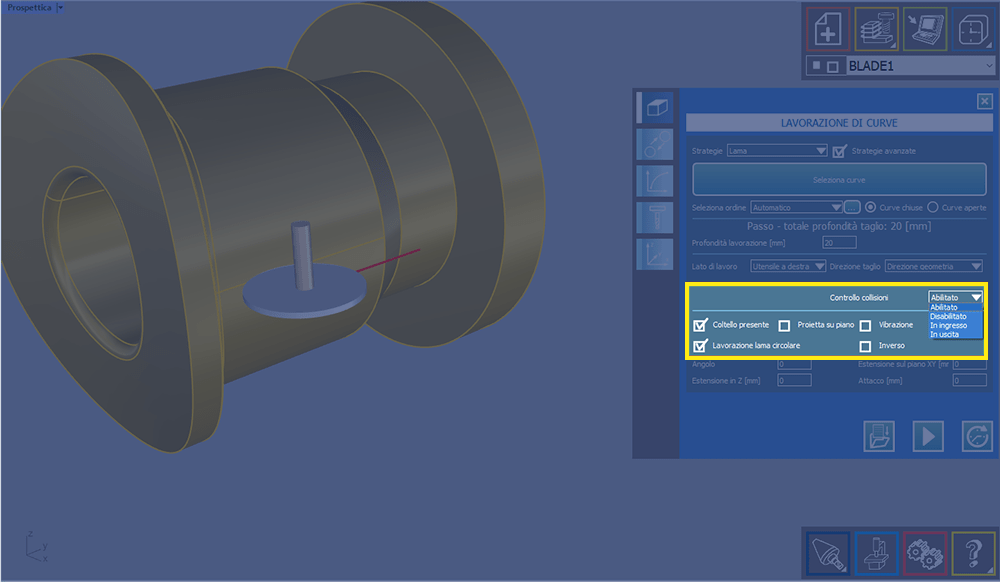

COLLISION CHECK IN CUTTING STRATEGY WITH CIRCULAR BLADE

The introduction of the collision check of circular blade tools into the cutting strategy allows the machining of both 2D and 3D geometries, controlling the diameter and thickness of the blade at each pass, in order to achieve the most complete cut and to preserve all geometric parts of the object to be cut.

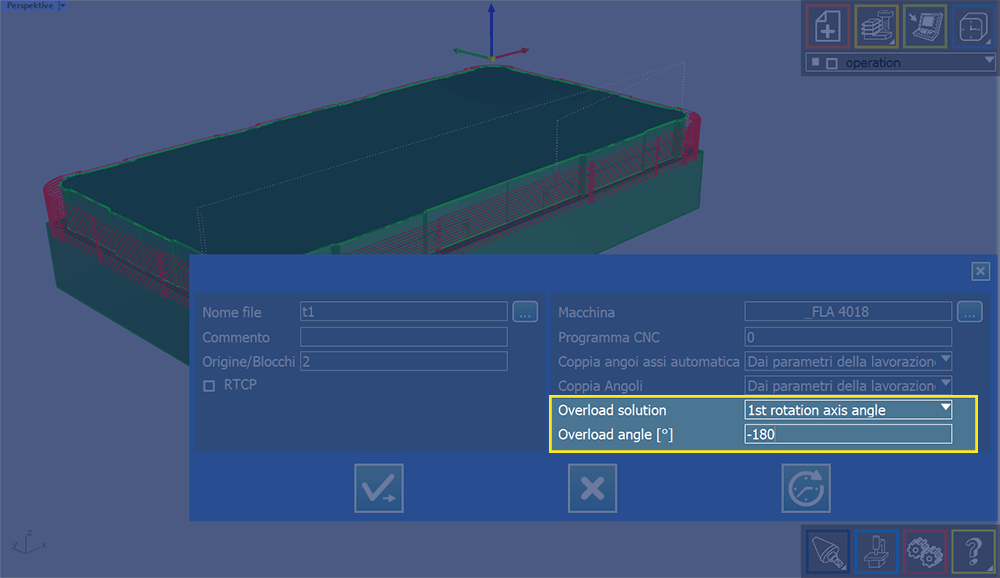

PRELOAD OPTION ON THE TURNING AXES OF THE MACHINE TOOL

During the postprocessor operation, it has been added the possibility of entering a pre-load value for the turning axis of the machine tool. This allows those who own an asymmetrical head milling machine to choose the best starting position to avoid unnecessary machine overruns, or cluttering of the moving parts of the milling machine that would not provide the desired results.

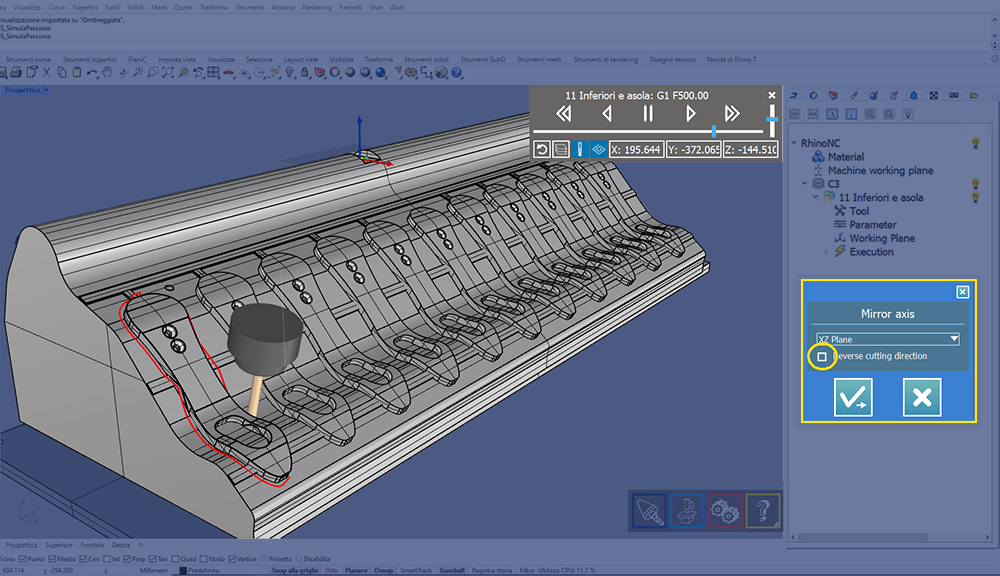

SELECTION OF TOOL PATH DIRECTION IN MIRRORING

We have introduced the possibility of changing and reversing toolpath direction by using automation that allows you to directly copy and mirror the machining strategy with respect to an axis. This is convenient for those working on symmetrical workpieces where the direction of the toolpath can be easily chosen according to the technological characteristics of their machine tool.

2021

EDGE SELECTION FROM 3D GEOMETRIES

Until now to use the same edge of 3D objects as a working curve, it was formerly necessary to select and extract the curves in Rhinoceros. Using this new version of RhinoNC, it is possible to directly select the edges of 3D geometries as curves from the working interface with no preliminary actions.

CUSTOMIZABLE INTERFACE

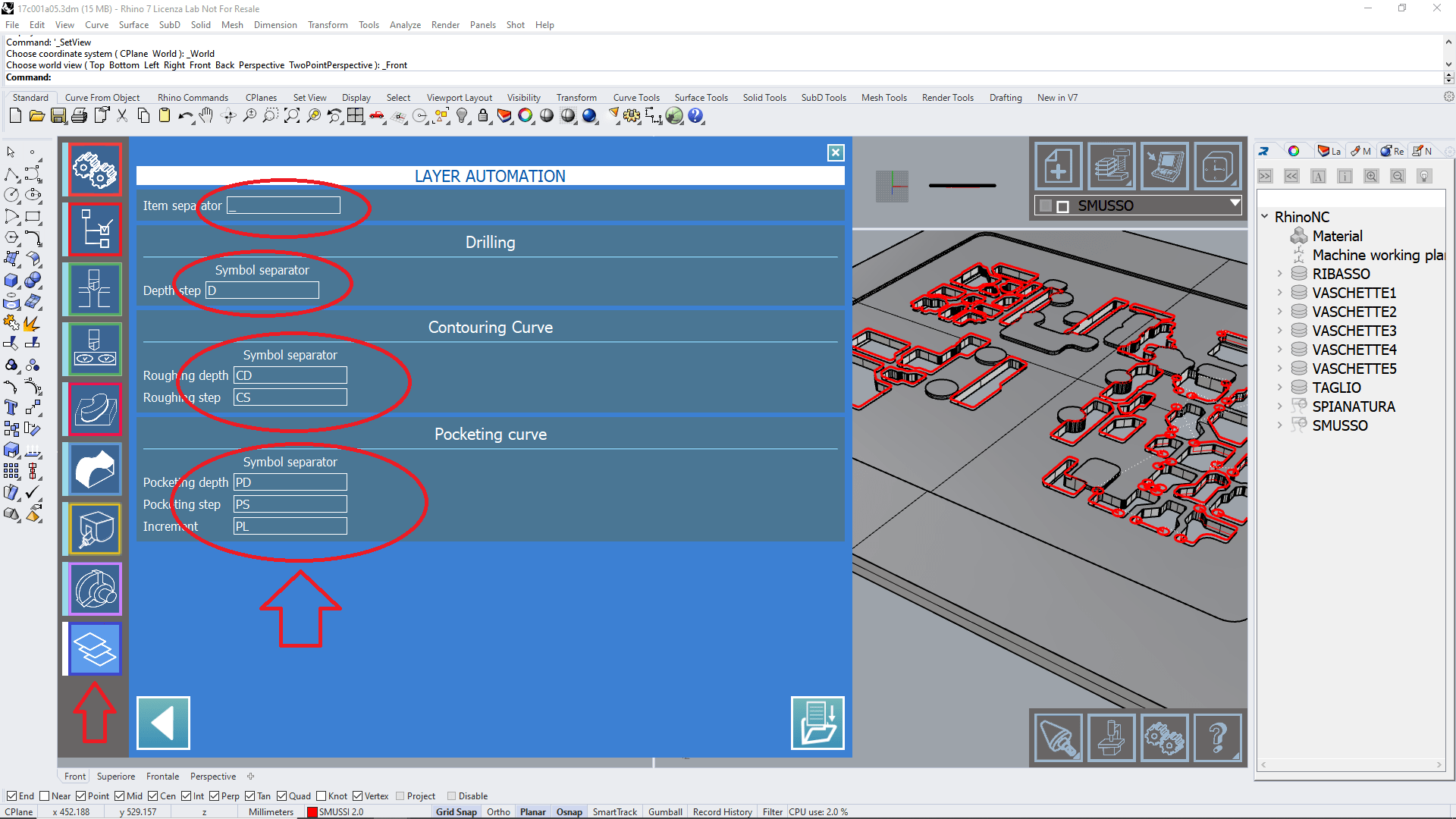

The user can now customize working parameters according to the most used/preferred actions. This configuration can be copied and easily transferred to other files with no need of any manual interaction. The software identifies geometries and automatically applies the parameters according to the user’s preference.

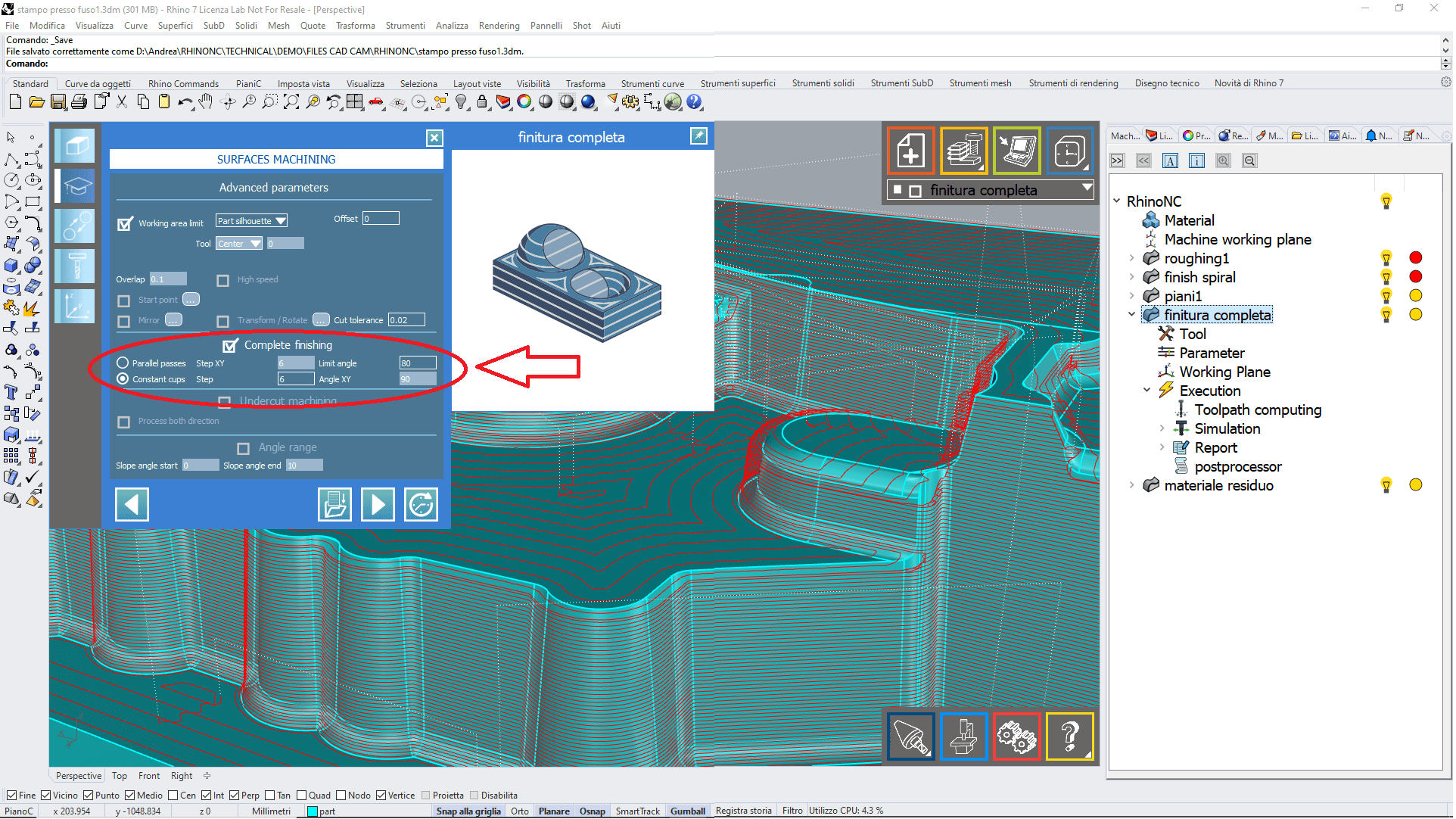

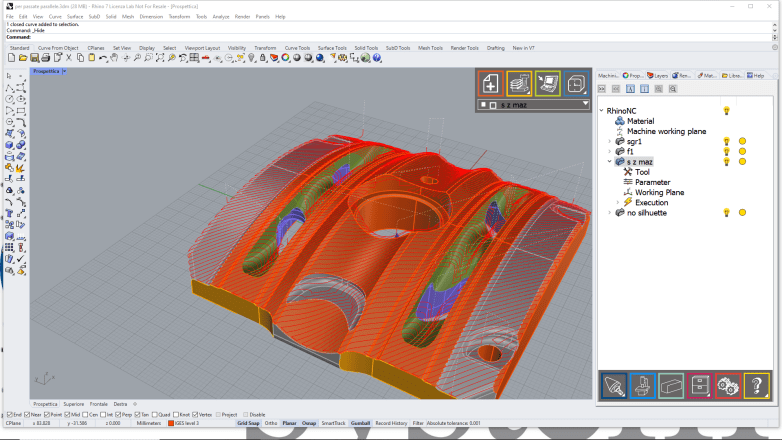

COMPLETE FINISHING STRATEGY

The Complete Finishing option allows the user to change, in the same machining, the type of working strategy with no need of dividing the geometry into several parts. It can be a parallel pass or constant crest machining in the flatter areas and guarantees a faster and more efficient calculation of the whole piece to be machined.

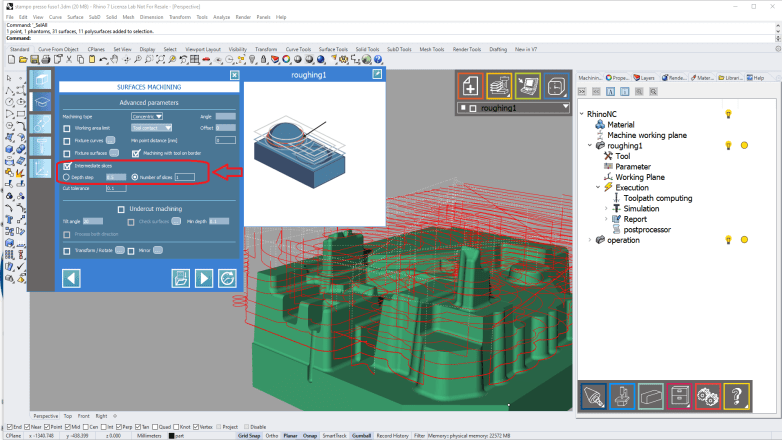

NEW AUTOMATIC MANAGEMENT OF APPROACHES

The improvement involves pocket emptying operations: the software is able to automatically recognize the object geometry and adopt the best approach movement to not cause any damage.

PERSONALIZED MANAGEMENT OF WORK STRATEGIES

RhinoNC is getting simpler by giving the user the possibility to choose how to view the list of strategies within the same process, for example in alphabetical order, by tool or material etc.

AUTOMATIC MANAGEMENT OF THE SAFETY PLAN

With the automatic recognition of the safety plane, the software automatically selects and positions the tool where it is most appropriate to create any damage to the work surface. Such an automatic operation reduces the risk of manual errors and object tampering.

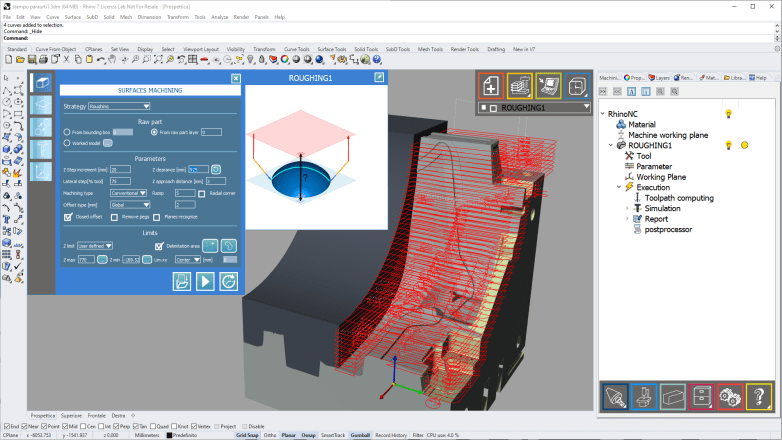

NEW OPTION “INTERMEDIATE SURFACE”

A command has been added to the Surface roughing strategy to allow users to generate intermediate working planes with a pre-set value. Moreover, the software automatically detects any other surface part that requires intermediate plane.

2020

CUSTOMIZATION OPTION IN CURVE MACHINING

It’s now possible to set a customized speed for entry and exit movements during the processing of curves.

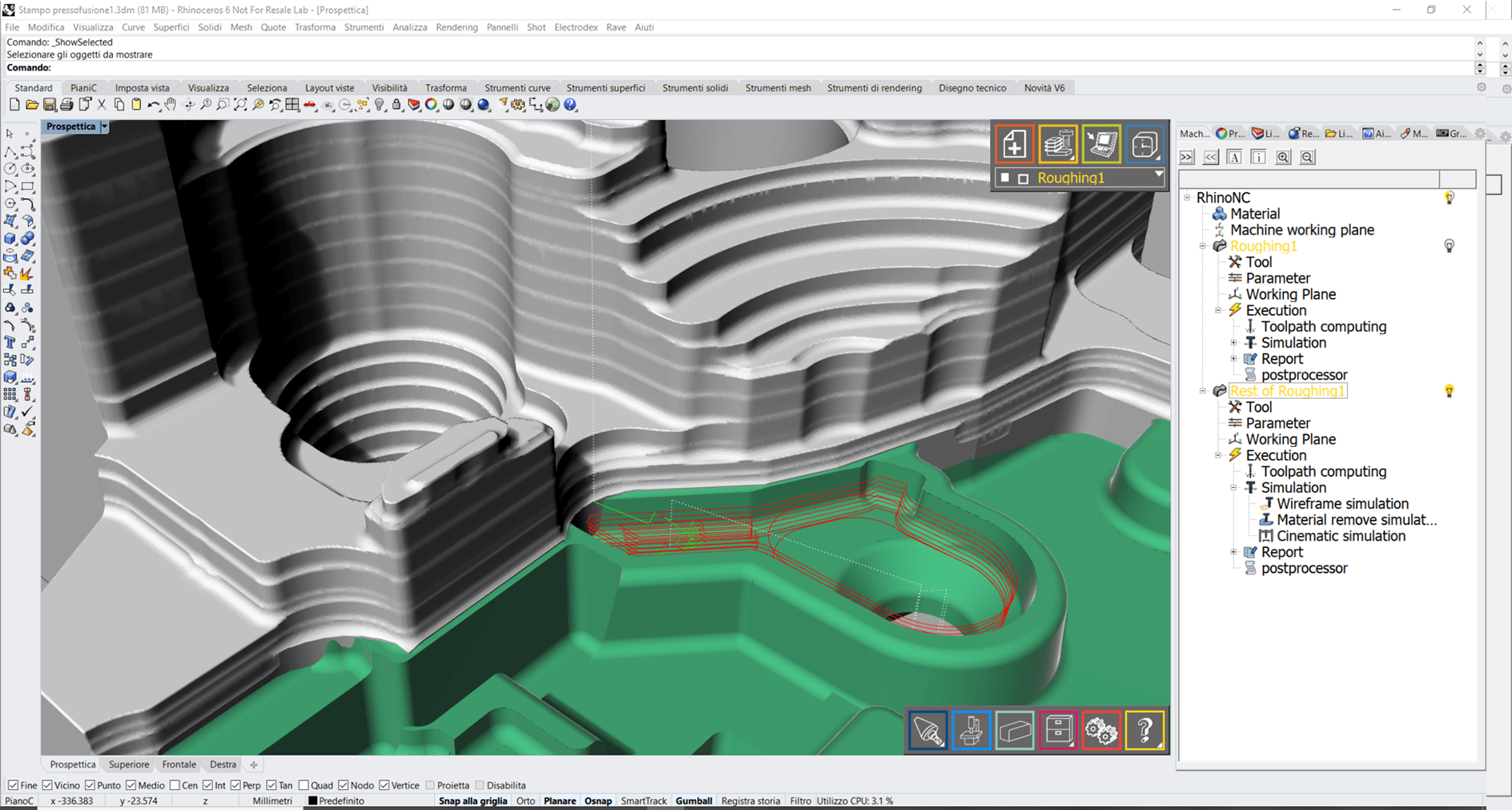

FINISHING OF RESIDUAL MATERIAL IN 3D GEOMETRY MACHINING

This particular function allows users to finish the areas where the tool left some residual material during the former processing. The 3D geometry machining strategy has been improved both in terms of calculation accuracy and optimized movement options.

DRAFT ANGLE OPTION IN CONTOUR FEATURES

The possibility of managing a draft angle in multi-step depth machining has been added. As a consequence, it is no longer necessary to build the 3D geometry to perform the contouring operations as you can work directly on curves.

COLLISION CHECKING IN CONTOURING MACHINING

The possibility of having an automatic control of any obstacles present along the tool path has been added in the process of curve contouring machining.

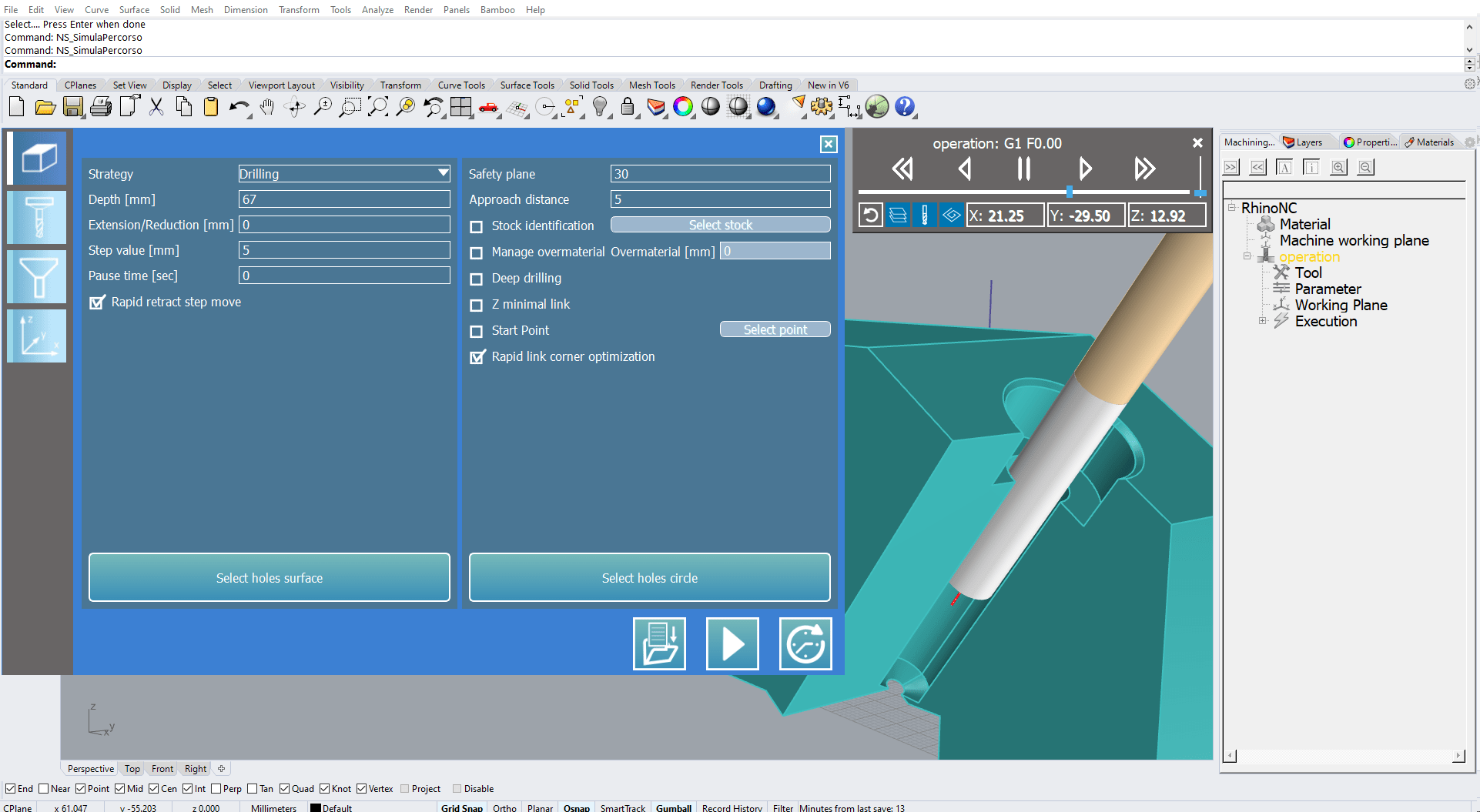

IMPROVED MACHINING IN DRILLING CYCLES

To improve the machining function of the drilling cycles, new options have been added as automatic recognition of diameters also on mesh entities and retraction movement in rapid mode.

NEW OPTION FOR SURFACE MANAGEMENT

The possibility of orienting the tool on a 4 or 5-axis machine has been added to create multi-origin machining, independent of Rhinoceros surface areas. This allows users to save time during machining as it is possible to work on several objects at the same time.

2019

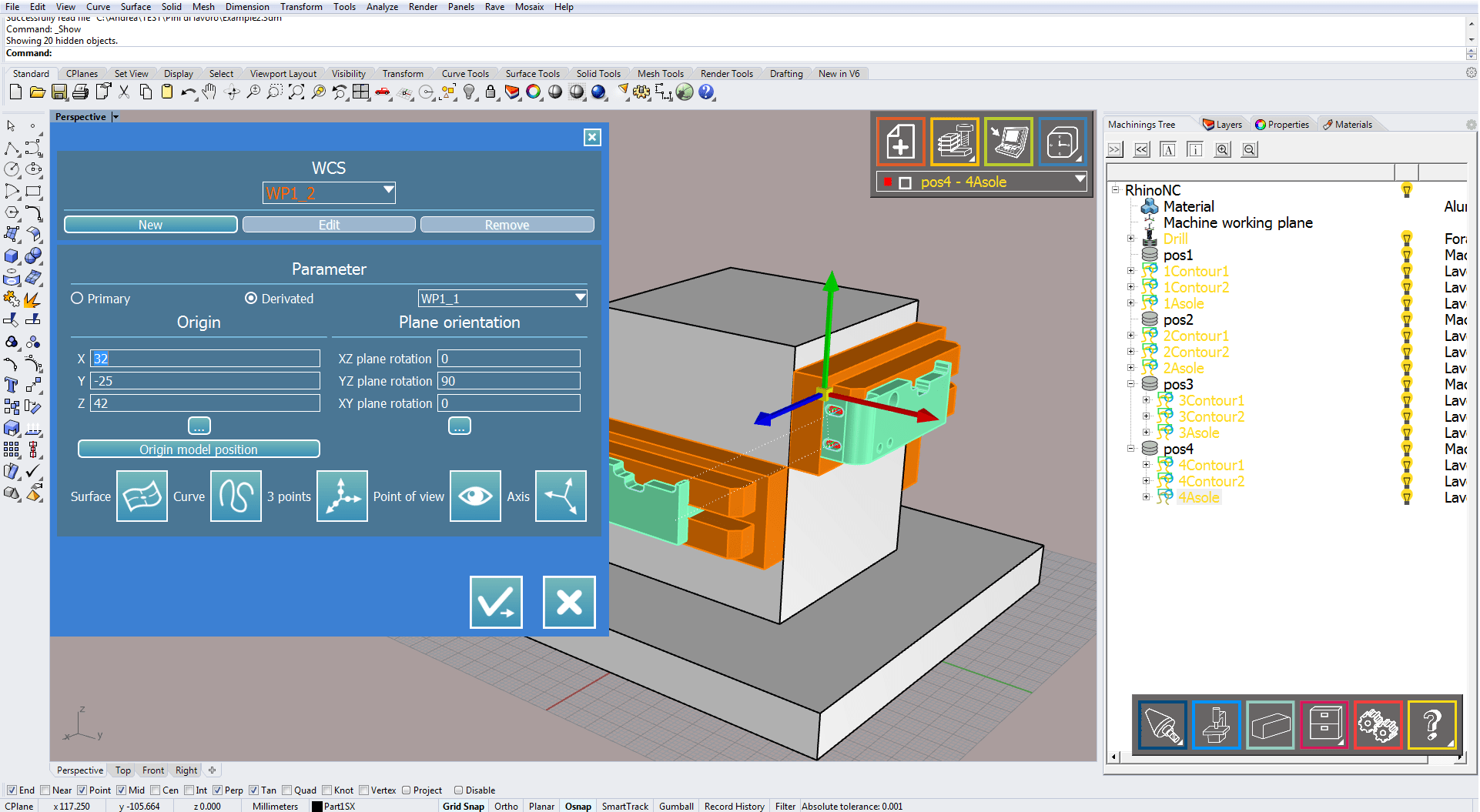

NEW ORIENTATION OPTION FOR WORKING SURFACE

The tool can be now rotated in any direction. This function is essential especially for those who work on 4 to 5 axes machines.

AUTOMATIC DRILLING

This is a strategy for the management of the drilling cycles that provides automatic recognition of the geometry together with the automatic recognition of the most suitable tool to be used. Now the users can reduce processing time and carry out a more precise processing.

SIMULATION WITH RESIDUAL MATERIAL

This function gives the user a preview of the residual material that will be removed during the processing phase.

Overview

Overview Features

Features News & Releases

News & Releases Requirements

Requirements Modules

Modules RhinoNC OPENLAB

RhinoNC OPENLAB Brochure

Brochure Video

Video